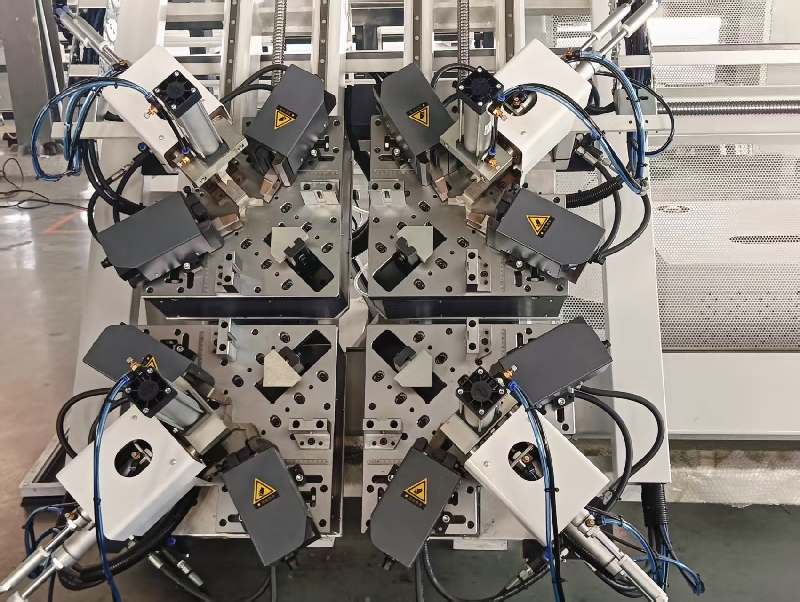

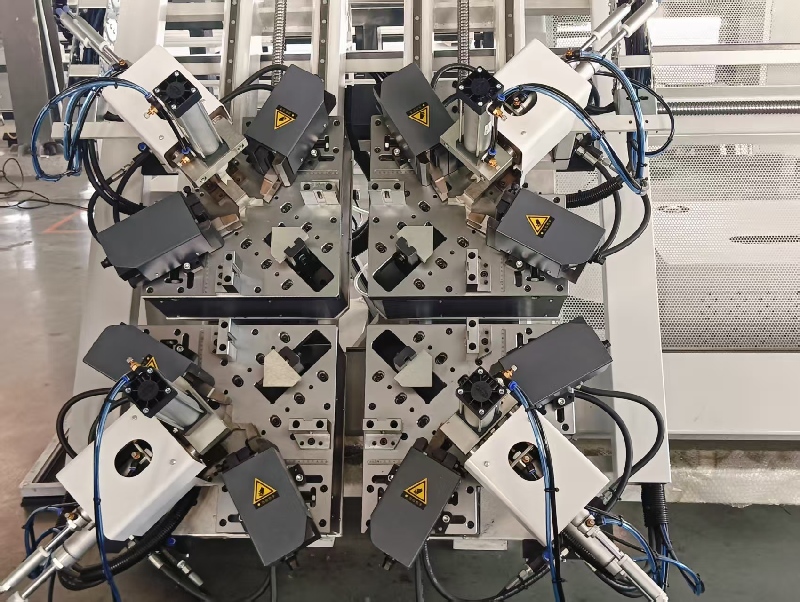

How should the four-head CNC corner crimping machine be maintained on a daily basis?

As a high-precision core device for aluminum door and window processing, the four-head CNC corner joining machine's daily maintenance directly impacts its machining accuracy, service life, and production efficiency. Maintenance should focus on five core elements—“cleaning, lubrication, tightening, inspection, and calibration”—and be executed in a tiered approach by day, week, month, and quarter. The specific plan is as follows:

I. Daily Maintenance (5-10 minutes before startup / after shutdown, mandatory items)

1. Cleaning and Organization

Use a high-pressure air gun or cloth to remove aluminum chips, dust, and oil residue from the machine surface, cornering heads, guide rails, lead screws, and clamping mechanisms. Focus on critical areas like cornering blades and angle bracket positioning slots (prevent chip jams causing cornering deviations).

Wipe the touchscreen and control panel to ensure responsive buttons and clear displays, preventing oil or dust from entering crevices.

Clear surrounding areas, keeping floors free of debris and oil to prevent tripping hazards and dust accumulation/moisture buildup beneath equipment.

2. Basic Inspections

Air Supply System: Verify air compressor pressure (must be stable between 0.5-0.8MPa). Check for leaks in air hoses and fittings. Ensure drain valves discharge promptly (prevent moisture ingress causing cylinder rust).

Hydraulic System: Verify oil tank level (between gauge markings), inspect hoses and cylinders for leaks, and confirm oil temperature is normal (below 60°C at ambient conditions).

Mechanical Components: Check corner heads and clamping blocks for looseness. Ensure guide rails and lead screws are free of oil contamination (no dry friction). Confirm limit switches and sensors are clean and unobstructed.

Electrical System: Verify secure connections for power and signal cables. Ensure plugs are tight and not overheating. Test emergency stop buttons for responsiveness and functionality.

3. Basic Lubrication

Apply a small amount of specialized lubricant (e.g., No. 32 hydraulic oil or machine tool guideway oil) to sliding surfaces like guideways and lead screws using a brush. Prevent dry friction (apply just enough to coat surfaces—avoid excess).

For moving joints like cylinder piston rods and pins, spray a small amount of rust-preventive lubricant (to prevent rust and binding).

II. Weekly Maintenance (15-20 minutes before closing on Fridays)

1. Thorough Cleaning and Lubrication

Remove the corner joint head cover and clear accumulated debris inside (especially aluminum shavings near the corner code stamping area). Wipe the corner joint cutting head and punch with kerosene or a specialized cleaner. Inspect the cutting head for wear or chipped edges (minor wear can be ground down; severe wear requires replacement).

Thoroughly clean core transmission components such as guide rails, lead screws, and ball nuts, then reapply lubricant to ensure smooth operation.

Clean the hydraulic tank filter and air source filter (use compressed air to blow out the filter; replace if severely clogged).

2. Tightening and Function Check

Use a wrench to tighten the fixing bolts of the equipment frame, corner joining mechanism, and clamping mechanism (focus on frequently stressed areas such as the corner joining cylinder base and guide rail fixing screws) to prevent loosening due to vibration.

Test the positioning accuracy of the CNC system: Input common profile dimensions (e.g., 1000×1500mm), initiate the automatic corner joining process, and verify accurate positioning at all four corners with diagonal error ≤1mm (calibrate promptly if out of tolerance).

2. Wear Part Replacement and System Inspection

Replace aged air hoses, oil lines, and seals (especially seals in high-pressure areas of the hydraulic system to prevent leaks).

Inspect tooling and mold wear, replacing severely worn components in batches (e.g., corner punches, locating pins, clamping rubber pads).

Perform comprehensive CNC system diagnostics: Back up system parameters (to prevent parameter loss), inspect hard drive and memory functionality, and update system software (if official updates are available).

3. Overall Equipment Commissioning

Conduct no-load trial operation: Start the equipment and run continuously for 30 minutes. Observe whether all mechanisms operate smoothly without abnormal noises or jamming, and ensure temperatures and pressures remain within normal ranges.

Perform load testing: Process corner joints using profiles of varying specifications (e.g., narrow frames, wide frames, insulated profiles). Verify corner joint accuracy and joint flatness meet requirements, then adjust equipment parameters to optimal settings.

V. Maintenance Precautions

Safety First: Before maintenance, disconnect power, shut off air supply, and relieve hydraulic system pressure (press the pressure relief valve) to prevent accidental equipment startup.

Lubrication Specifications: Use designated lubricants for each component (e.g., hydraulic oil for hydraulic systems, guide rail oil for rails, pneumatic oil for pneumatic parts). Do not mix lubricants and prevent contamination of profile machining surfaces.

Cleaning Restrictions: Do not use high-pressure water to directly rinse equipment (especially electrical control cabinets and touchscreens) to avoid moisture ingress causing short circuits. When cleaning cutting tools, do not touch cutting edges directly with hands (to prevent cuts).

Record Traceability: Maintain a maintenance log documenting each session's date, activities, identified issues, and resolutions (e.g., replaced part numbers, calibrated parameters) to facilitate future troubleshooting.

Professional Operations: Complex procedures like CNC system parameter calibration, hydraulic pump disassembly, or servo motor repairs must be performed by trained technicians. Unauthorized disassembly by non-professionals is strictly prohibited.

VI. Common Faults and Quick Fixes (Frequently Encountered During Maintenance)

Fault Symptom Possible Cause Resolution

Large deviation in corner assembly accuracy Aluminum chips jammed, insufficient guide rail lubrication, positioning parameter offset Clean corner assembly head and guide rails, re-lubricate, calibrate positioning parameters

Insufficient corner assembly pressure Insufficient hydraulic oil, internal leakage in hydraulic pump, pressure reducing valve malfunction Top up hydraulic oil, inspect hydraulic pump and pressure reducing valve, replace damaged components

Clamping mechanism fails to operate Insufficient air supply pressure, air cylinder leakage, limit switch malfunction Adjust air supply pressure, inspect air lines and cylinder, clean limit switch

Touchscreen unresponsive Surface oil/dust contamination, loose signal cable, power supply failure Clean touchscreen, inspect signal cable and power supply, restart equipment

Abnormal equipment noise Dry grinding of guide rails, loose lead screw, motor failure Reapply lubrication, tighten lead screw and motor mounting bolts, inspect motor

Verify stable corner-joining pressure: Monitor hydraulic pressure display (rated 15MPa) via touchscreen. Test for uniform pressure during different profile cornering operations, ensuring no sudden pressure spikes or drops.

3. Rust Prevention

For exposed metal surfaces (e.g., frame, corner-joining head housing), wipe with a dry cloth and apply a thin layer of rust-preventive oil (especially in humid environments to prevent oxidation and rust).

Inspect anti-rust status of wear-prone components like cutting tools and molds. Apply rust-preventive oil or wrap with moisture-proof paper during downtime.

III. Monthly Maintenance (Last week of each month, 30-40 minutes)

1. System Maintenance

Hydraulic System: Inspect hydraulic oil cleanliness (replace immediately if oil appears blackened or contains contaminants; clean reservoir and filter screen during replacement). Hydraulic oil should generally be changed every 6-12 months (adjust based on usage frequency).

Air Supply System: Replace filter elements and lubricant in the air receiver unit (filter, pressure regulator, lubricator). Refill the lubricator with dedicated pneumatic oil to ensure cylinder lubrication.

Electrical System: Open the electrical control cabinet. Use compressed air (low pressure) to blow out internal dust (prevent short circuits caused by dust accumulation). Inspect whether the contacts of contactors and relays are oxidized (if severely oxidized, grind or replace them). Check if the cooling fan is operating normally.

2. Accuracy Calibration and Component Inspection

Calibrate the positioning accuracy of the CNC system: Use a laser distance meter or tape measure to measure the travel distance of the corner forming head. Compare this with the touchscreen display value. If the error exceeds 0.05mm, compensate via system parameters (requires professional operation).

Inspect the wear level of the corner forming cutter head and punch: Measure the thickness of the cutter edge. If wear exceeds 0.2mm, or if burrs appear in the corner seam after punching,