Advantages and Features of CNC Cutting Saw with Automatic Feeding and Cutting

In industries such as metal processing, aluminum profile fabrication, and wood cutting, precision and efficiency serve as critical indicators of a company's core competitiveness. With the acceleration of manufacturing upgrades and intelligent trends, CNC cutting saws equipped with automatic feeding and cutting functions are progressively replacing traditional manual operations. This not only optimizes production processes but also significantly enhances product quality and delivery speed.

1. Advantages of Automatic Feeding

① Precise Control of Feed Length

CNC systems allow setting feed length parameters, eliminating manual measurement errors and ensuring consistent cutting dimensions.

② Enhanced Work Efficiency

Automated feeding eliminates manual material handling. Continuous operation reduces waiting time, making it ideal for batch production.

③ Reduced Labor Intensity

Automated feeding minimizes frequent material handling and manual alignment tasks, improving the working environment for operators.

2. Advantages of Automatic Cutting

① High-Precision Stable Cutting

The CNC system automatically adjusts cutting speed and position based on saw blade parameters, ensuring flatness and precision of cut surfaces.

② Support for Complex Cutting Patterns

Capable of bevel cuts, multi-angle cuts, and even multi-segment combination cuts to meet diverse product manufacturing requirements.

③ Reduced Scrap Rate

Automatic positioning and precise control minimize material waste, saving costs.

3. Technical Features

Integrated CNC System: Programs can be written and modified via touchscreen or computer.

Intelligent Detection and Safety Protection: Automatically detects material position during feeding to prevent jams or empty cuts.

Compatible with Multiple Materials: Processes various materials including aluminum, copper, stainless steel, and wood.

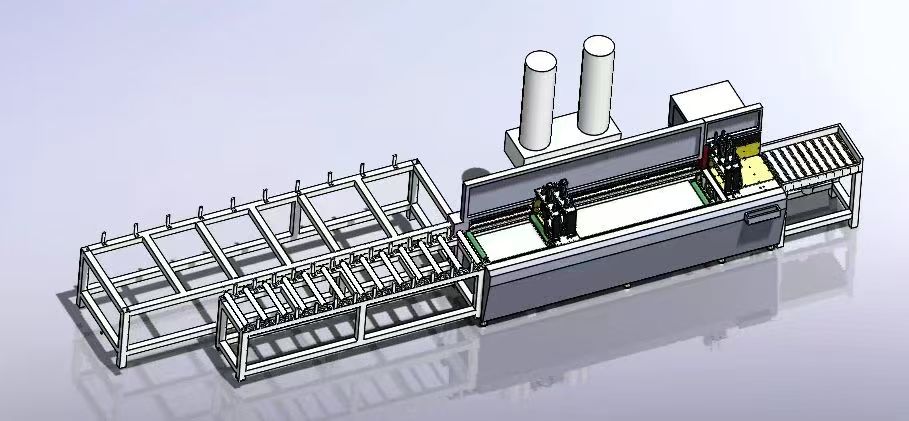

Interoperable with Production Lines: Connects to loading racks and unloading conveyors for fully automated production.

4. Enterprise Application Cases

In aluminum alloy profile processing plants, automated feeding and cutting boosts production capacity by over 30% while controlling dimensional tolerances to ±0.1mm, significantly reducing rework rates. For furniture manufacturers, automated cutting enables standardized batch production of parts, shortening delivery cycles.

5. Conclusion

The automated feeding and cutting technologies of CNC cutting saws represent not only enhanced production efficiency but also a crucial manifestation of digitalization and intelligent manufacturing. For enterprises pursuing high efficiency, low costs, and high precision, this constitutes a worthwhile technological investment.