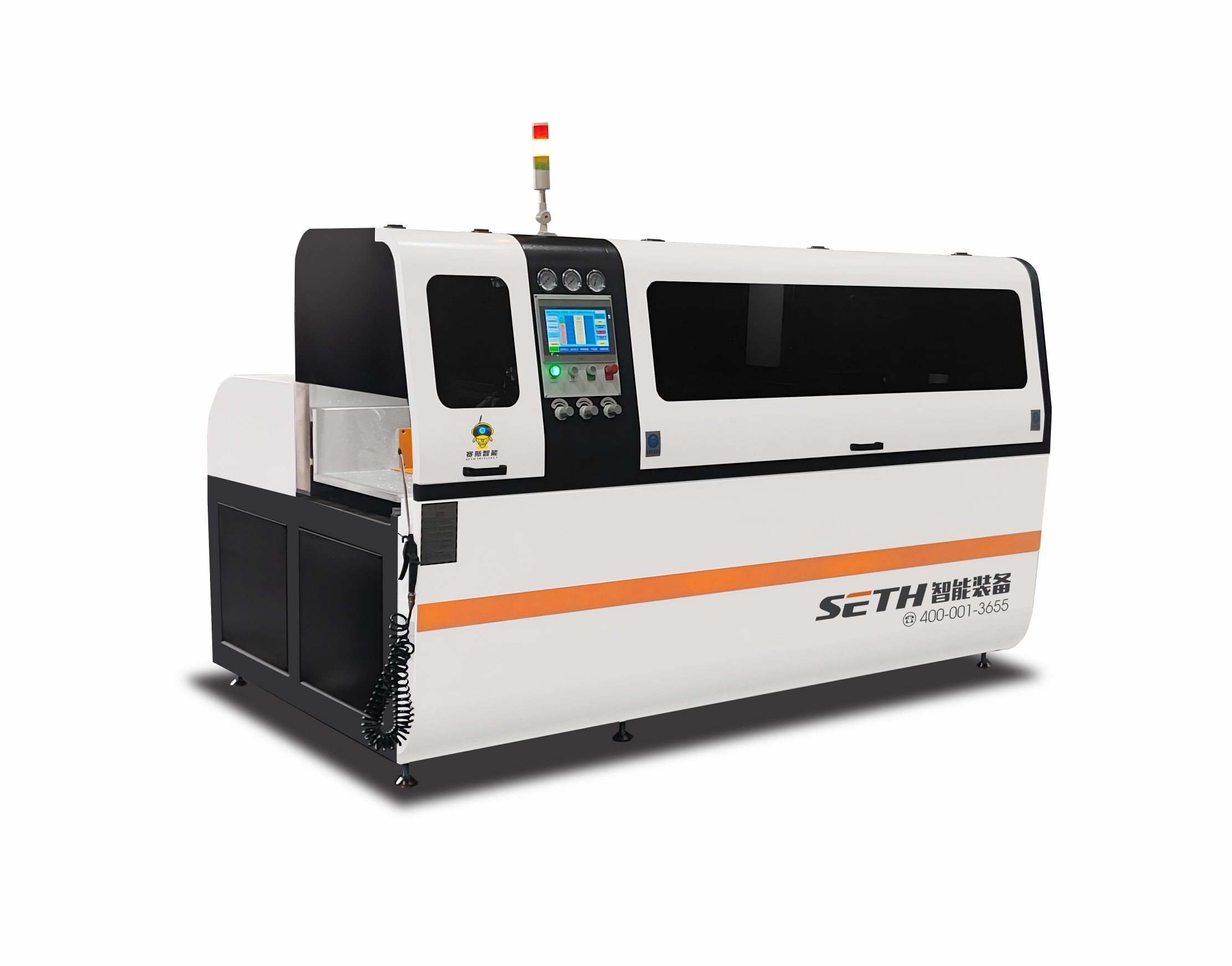

Full CNC Automatic Aluminum Cutting Machine – 550 mm Saw Blade

Full CNC Control: Automated cutting programs with customizable parameters for batch processing and varied profile designs.

550 mm Industrial Saw Blade: Large‑diameter blade delivers excellent stability, reduces cutting vibration, and improves lifespan.

Automatic Feeding System: Servo‑driven infeed with precision linear guides for consistent material positioning.

High Cutting Speed: Optimized spindle and feed rates for faster production.

Safety Systems: Enclosed cutting area, emergency stop functions, and dust extraction interface for operator safety.

Durable Construction: Heavy‑duty machine bed and rigid frame minimize deflection, ensuring sustained accuracy.

Energy Efficiency: Servo drive technology reduces power consumption compared to traditional hydraulic systems.

Full CNC Fully Automatic Aluminum Cutting Machine – 550 mm Saw Blade

Product Overview:

The full CNC fully automatic aluminum cutting machine equipped with a 550 mm saw blade is a high‑performance industrial solution for precise and efficient cutting of aluminum profiles. Designed for large‑scale manufacturing and continuous operation, it integrates advanced computer numerical control technology with automatic feeding, clamping, and cutting systems. Its robust structure and intelligent software interface make it ideal for producing high‑quality aluminum components for windows, doors, curtain walls, and industrial products.

This machine is engineered to deliver exceptional cutting accuracy and repeatability, while minimizing waste and optimizing throughput. The 550 mm diameter tungsten‑carbide‑tipped saw blade ensures smooth cuts with clean edges, even on thick or complex profile cross‑sections.

Advantages

High Accuracy & Repeatability: Achieves ±0.1 mm tolerance over long production runs.

Reduced Labor Costs: Fully automated operation decreases manual input, ideal for unmanned shifts.

Versatility: Handles a wide range of profile sizes and wall thicknesses.

Cleaner Cuts: Minimizes burrs, reducing or eliminating secondary processing.

Long Tool Life: Industrial‑grade saw blade and efficient cutting parameters maximize blade longevity.

Data Integration: Capable of connecting to MES or ERP systems for smart factory environments.

Typical Applications

Cutting aluminum profiles for window and door manufacturing.

Fabricating curtain wall components for architectural projects.

Producing precision‑cut parts for transportation and electronics industries.

Preparing extrusion profiles for assembly in automated production lines.

Large‑scale cutting operations in aluminum furniture and framing production.

Fully Automatic CNC Aluminum Cutting Machine: Integrates automatic feeding, length measurement, clamping, and material removal throughout the entire process. Supports multi-angle cutting at 45°, 90°, and other angles, achieving precision within ±0.05-0.1mm. Capable of 300-800 cuts per hour, it serves as core equipment for aluminum profile mass production. Widely used in automotive components, building curtain walls, and other fields.

- Specialized Aluminum Cutting Machines: Includes high-speed cutters (suitable for thin aluminum parts 1-10mm thick, such as electronic enclosures) and heavy-duty aluminum cutters (capable of processing 100-200mm thick aluminum for aerospace component fabrication). Customization is required based on specific operational conditions.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible