Advantages and Features of the Four-Head CNC Corner crimping Machine

Advantages and Features of Four-Head CNC Corner Joining Machines:

Focusing on Core Values of Efficiency, Precision, and Reliability

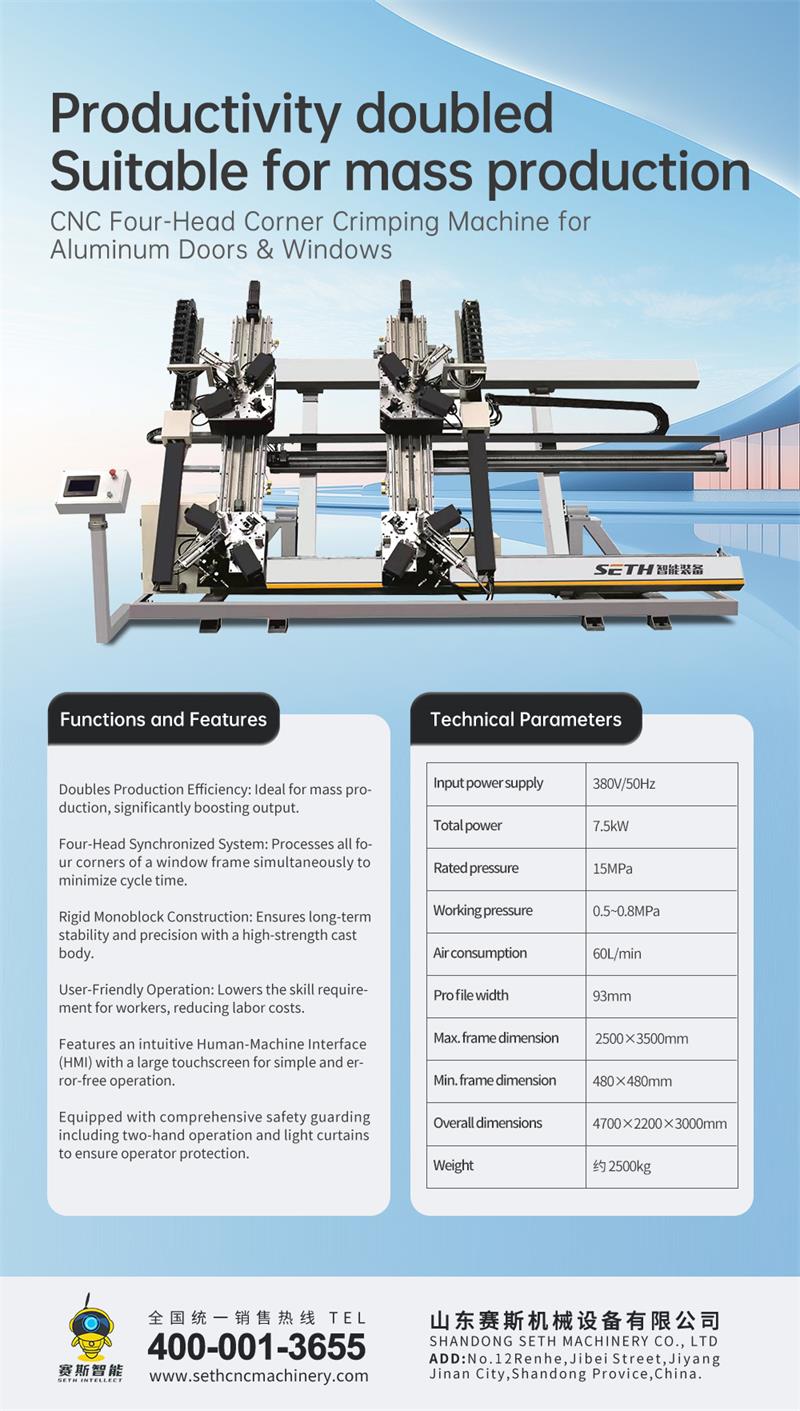

As core equipment for aluminum door/window and curtain wall fabrication, the four-head CNC corner joining machine delivers advantages across five key dimensions:

processing efficiency, corner joining precision, operational convenience, structural reliability, and adaptability to diverse applications. It simultaneously balances production cost control and investment returns, fully meeting industrial production's core demands for “high efficiency, precision, stability, and versatility.” Specific features include:

I. Core Efficiency Advantage: Doubled Output for Scalable Production

Four-head simultaneous processing achieves exponential output growth

Unlike dual-head corner joining machines limited to “two corners per pass,” the four-head model enables simultaneous clamping and joining of all four corners (for rectangular workpieces). Eliminating secondary positioning adjustments reduces processing time per piece by over 50% (e.g., standard 600×800mm door/window frames require only 15-20 seconds per piece). For mass production scenarios, daily output capacity can reach 800-1200 sets per shift, significantly reducing per-unit processing time costs.

High automation integration reduces manual intervention

Equipped with a CNC system (e.g., PLC + touchscreen) supporting parameter presets (corner bracket specifications, corner pressing pressure, clamping time, etc.), it automatically completes the entire process—“clamping → corner pressing → pressure release → reset”—after workpiece positioning, eliminating real-time manual operation. Select high-end models can interface with production line loading/unloading robots, enabling unmanned processing to reduce labor costs and human operational errors.

Exceptional continuous operation stability with zero downtime losses

Features independent hydraulic/pneumatic drive units (four-head independent control with individual start/stop capability), paired with a large-capacity oil tank and cooling system. Supports 8 hours of uninterrupted operation without pressure issues, eliminating downtime caused by equipment overheating or power shortages to ensure smooth production line flow.

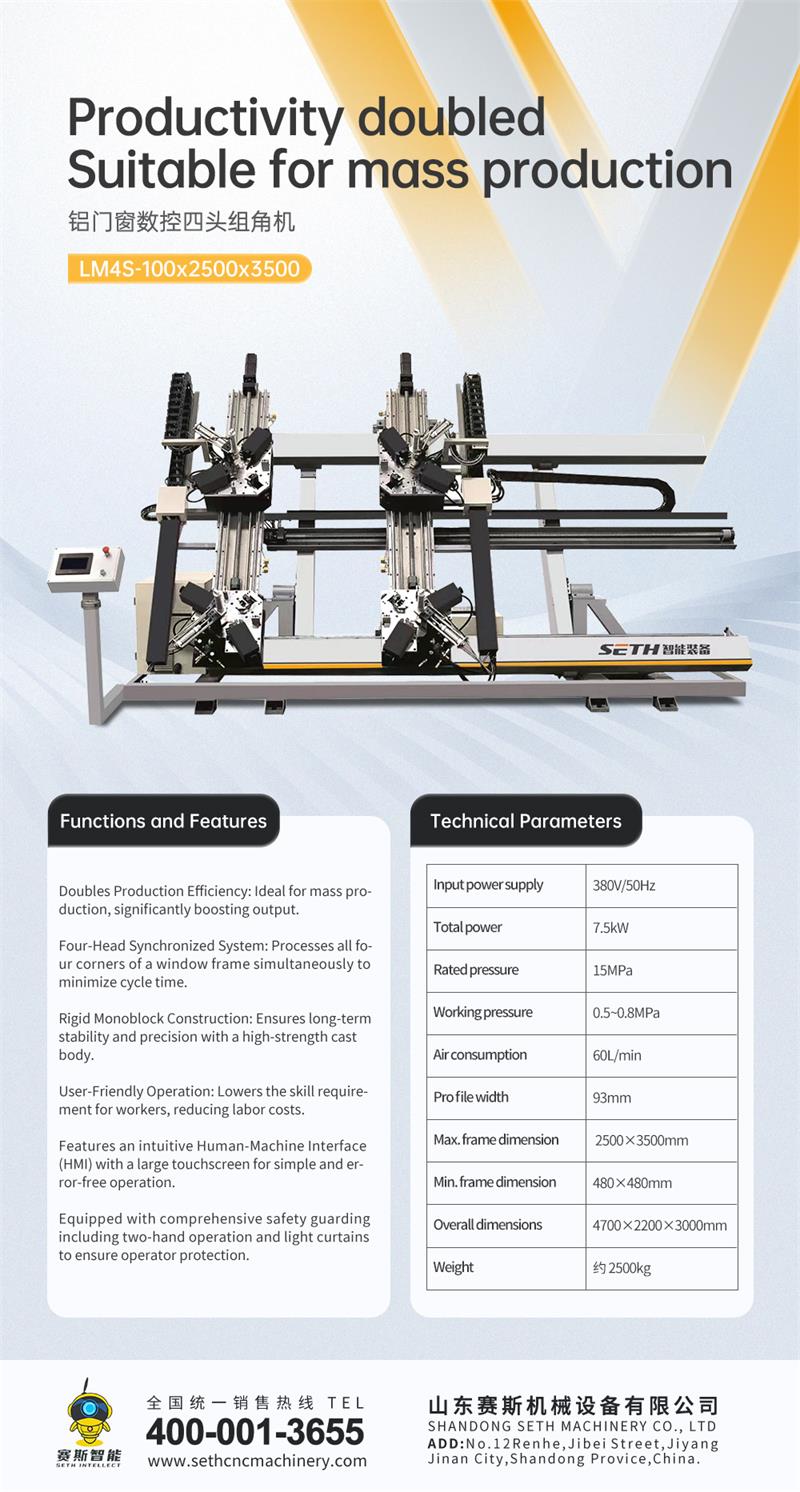

II. Precision Control Advantages: Millimeter-Level Tolerance Ensures Product Consistency

CNC Positioning + Rigid Structure Achieve Industry-Leading Corner Assembly Accuracy

Positioning Accuracy: Servo motor-driven worktable with X/Y-axis positioning error ≤±0.05mm ensures consistent perpendicularity and parallelism between all four corner positions and the workpiece reference plane.

Corner Assembly Precision: Corner gap ≤0.1mm, diagonal deviation ≤0.3mm/meter (significantly exceeding the industry standard of 0.5mm/meter). Assembled workpieces exhibit zero warping or chipped corners, eliminating the need for post-processing correction or grinding.

Closed-loop pressure control adapts to varying profile thicknesses

Four independent pressure sensors provide real-time feedback (adjustable range 0-20MPa). The CNC system automatically compensates for pressure deviations, ensuring uniform clamping for aluminum profiles ranging from 1.4-3.0mm thick (e.g., thermal break aluminum, curtain wall profiles). This prevents deformation in thin profiles and weak corner joints in thick profiles.

Automatic corner bracket positioning minimizes human error

Select models feature a corner bracket pre-positioning device. CNC programs set installation locations, automatically pushing and precisely positioning brackets to ensure full cavity contact with profiles, enhancing corner joint strength (tensile strength ≥3500N, compliant with GB/T 8478-2020 door/window standards).

III. Operational & Adaptability Advantages: Lower Barriers, Meet Diverse Scenarios

User-friendly interface for quick novice adoption

Equipped with a 10-15 inch touchscreen supporting Chinese/English operation. Built-in parameter library for common components (e.g., casement windows, sliding doors, curtain wall panels) allows direct parameter recall or modification. Features self-diagnostic functions (e.g., low pressure, positioning deviation, high oil temperature) with real-time fault code display and solutions to lower maintenance barriers.

Multi-Specification Compatibility, Eliminating Frequent Tooling Changes

Wide workpiece dimensions: Processes rectangular components ranging from 300-3000mm width and 300-2500mm height, accommodating everything from residential doors/windows to large curtain wall panels.

Profile Type Compatibility: Processes diverse aluminum alloy profiles including casement windows, sliding doors, sunroom frames, and curtain wall columns (compatible with corner bracket sizes 14×14mm-25×25mm). Changeovers require only parameter adjustments without mechanical mold replacement, completing in ≤5 minutes.

Flexible Processing Modes for Batch and Custom Production

Supports both “Batch Continuous Processing” and “Single-Piece Custom Processing”: Batch production enables continuous import of processing lists with automated cycle operations; customized orders allow rapid parameter modification without re-calibration, accommodating small-batch, multi-variety production demands.

IV. Structural and Reliability Advantages: Enhanced Durability, Reduced Total Cost of Ownership

Heavy-duty chassis design with outstanding vibration resistance

Chassis constructed from Q235 steel plate with full-welded construction + stress-relief treatment