Equipment Required for Aluminum Profile Processing

Equipment Required for Aluminum Profile Processing

Aluminum profile processing involves a series of specialized steps to transform raw aluminum extrusions into finished products that meet industry-specific requirements. Each stage of processing relies on distinct equipment, tailored to leverage aluminum’s properties—such as its malleability, lightweight, and corrosion resistance—while ensuring precision, efficiency, and quality. Below is a detailed breakdown of the key equipment used in aluminum profile processing, organized by core processing stages.

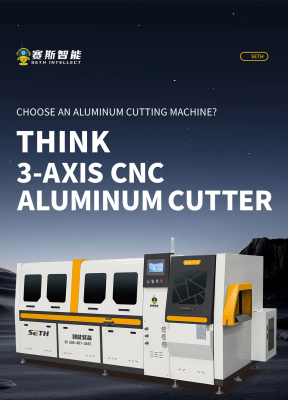

1. Cutting Equipment: Shaping Profiles to Basic Sizes Cutting is the initial step in aluminum profile processing, where extruded aluminum bars (or "billets") are trimmed to required lengths or cut into preliminary shapes. The choice of cutting equipment depends on the profile’s thickness, complexity, and precision needs. Circular Saw Machines: Widely used for straight, high-speed cutting of aluminum profiles. Equipped with tungsten carbide-tipped (TCT) blades, these machines can handle profiles of varying widths (from small decorative bars to large structural sections). They often feature automatic feeding systems to ensure consistent cutting lengths, making them ideal for mass production (e.g., cutting window frame profiles or furniture components).

Band Saw Machines: Suitable for cutting thicker or irregularly shaped aluminum profiles (e.g., heavy-duty structural beams). Band saws use a continuous, flexible blade with fine teeth, allowing for smooth cuts on large cross-sections without damaging the profile’s surface. They are commonly used in construction and machinery manufacturing for prepping large aluminum components. CNC Cutting Machines: For high-precision, complex cutting tasks (e.g., creating notches, holes, or custom contours in aluminum profiles). These computer-controlled machines integrate laser, plasma, or router technologies—laser cutting, in particular, delivers ultra-fine cuts with minimal heat damage, making it ideal for electronic or aerospace aluminum parts.

2. Extrusion Equipment: Forming Profiles into Custom Shapes Extrusion is the core process that transforms aluminum billets into profiles of specific cross-sections (e.g., rods, tubes, or complex structural shapes). This stage requires heavy-duty equipment designed to withstand high pressure. Aluminum Extruders: The primary machine in this stage, consisting of a hydraulic press, extrusion die, and heating system. First, aluminum billets are heated to 400–500°C (softening but not melting the metal). The heated billet is then pushed through a custom-designed steel die (with the desired cross-section) using hydraulic pressure (ranging from 1,000 to 10,000 tons). Extruders are categorized by their press capacity—smaller extruders (≤2,000 tons) for thin profiles (e.g., curtain rods), and larger ones (≥5,000 tons) for thick structural profiles (e.g., train carriage frames). Die Heating Ovens: Essential for preheating extrusion dies to 300–400°C. Heating the die ensures uniform metal flow during extrusion, preventing defects like cracks or uneven surfaces. Cooling Systems: After extrusion, profiles are rapidly cooled to stabilize their shape. This typically involves water quenching tanks (for fast cooling of high-strength alloys) or air cooling conveyors (for more gradual cooling of delicate profiles, such as electronic heat sinks).

3. Surface Treatment Equipment: Enhancing Durability and Aesthetics Aluminum profiles often require surface treatment to improve corrosion resistance, add color, or create texture. The most common treatments—anodizing, powder coating, and electrophoresis—rely on specialized equipment. Anodizing Equipment: Used to create a protective oxide layer on the aluminum surface. The process involves submerging profiles in an electrolyte solution (e.g., sulfuric acid) and applying an electric current. Key equipment includes: Anodizing Tanks: Large, acid-resistant tanks for holding the electrolyte and profiles. Rectifiers: Devices that supply controlled DC current to form the oxide layer (thicknesses range from 5–25 μm for decorative use to 50+ μm for industrial applications). Sealing Ovens: After anodizing, profiles are heated in these ovens (160–200°C) to seal the oxide layer, enhancing its corrosion resistance. Powder Coating Equipment: Applies a dry powder (polyester, epoxy, or acrylic) to the aluminum surface, which is then cured to form a hard, durable finish. Equipment includes: Electrostatic Spray Guns: Charge the powder particles, which adhere to the grounded aluminum profile (ensuring even coverage).

Curing Ovens: Heat the coated profiles to 180–220°C, melting and bonding the powder to the surface. This process is widely used for outdoor profiles (e.g., building facades) due to its weather resistance. Electrophoresis Coating Equipment: Similar to anodizing but uses a water-based paint instead of an electrolyte. Profiles are submerged in a paint bath and charged, causing the paint particles to deposit on the surface. The coated profiles are then cured in ovens. This method produces a smooth, uniform finish and is often used for interior profiles (e.g., furniture frames or door handles).

4. Machining Equipment: Adding Precision Features After cutting and forming, aluminum profiles may require additional machining to add holes, threads, slots, or other detailed features. This stage uses equipment similar to metalworking machinery but optimized for aluminum’s softness. CNC Milling Machines: For creating 3D features (e.g., grooves, pockets, or custom contours) on aluminum profiles. Equipped with rotating cutting tools, these computer-controlled machines ensure high precision—critical for aerospace or automotive components (e.g., engine brackets). Drilling Machines: Used to drill holes of various sizes in profiles. CNC drilling centers are preferred for mass production, as they can drill multiple holes in a single cycle with minimal human error. For small-scale operations, manual or semi-automatic drilling machines are sufficient. Tapping Machines: Create internal threads in pre-drilled holes. These machines use tapping tools (threaded drills) to cut threads, which are essential for assembling aluminum parts (e.g., attaching brackets to structural profiles).

5. Assembly and Finishing Equipment: Finalizing Products

The final stage involves assembling processed profiles into end products and adding finishing touches to ensure functionality and aesthetics.

Assembly Jigs and Fixtures: Custom-designed tools that hold aluminum profiles in place during assembly (e.g., joining window frames or furniture components). They ensure alignment and consistency, reducing errors in manual or automated assembly.

Fastening Tools: Including pneumatic riveters (for joining profiles with rivets), electric screwdrivers (for securing screws), and adhesive dispensers (for bonding profiles with industrial adhesives—common in lightweight applications like electronic enclosures).

Polishing and Deburring Machines: Remove sharp edges (burrs) and smooth surfaces after cutting or machining. Abrasive belt polishers are used for large profiles, while vibratory deburring machines handle small, delicate parts (e.g., decorative aluminum trim).

5. Assembly and Finishing Equipment: Finalizing Products

The final stage involves assembling processed profiles into end products and adding finishing touches to ensure functionality and aesthetics.

Assembly Jigs and Fixtures: Custom-designed tools that hold aluminum profiles in place during assembly (e.g., joining window frames or furniture components). They ensure alignment and consistency, reducing errors in manual or automated assembly.

Fastening Tools: Including pneumatic riveters (for joining profiles with rivets), electric screwdrivers (for securing screws), and adhesive dispensers (for bonding profiles with industrial adhesives—common in lightweight applications like electronic enclosures).

Polishing and Deburring Machines: Remove sharp edges (burrs) and smooth surfaces after cutting or machining. Abrasive belt polishers are used for large profiles, while vibratory deburring machines handle small, delicate parts (e.g., decorative aluminum trim).

Conclusion Aluminum profile processing relies on a diverse range of equipment, each tailored to a specific stage—from extrusion (shaping raw aluminum) to cutting, machining, surface treatment, and assembly (finalizing products). The choice of equipment depends on factors like profile complexity, production volume, and industry requirements (e.g., aerospace demands ultra-precision CNC machines, while construction prioritizes high-capacity extruders). As aluminum continues to gain traction in sustainable and high-tech industries, advancements in equipment (such as more energy-efficient extruders or AI-powered CNC systems) will further enhance processing efficiency, quality, and environmental performance.