Single Head CNC Cutting Saw Machine Continuous Cutting Saw

The core advantages of aluminum cutting machines, based on their performance and application characteristics, can be summarized as follows:

High processing precision: Fully automatic CNC models achieve accuracy of ±0.05-0.1mm, with angular deviation controlled within ±0.1°, delivering smooth, burr-free cuts that meet the demands of high-end sectors such as electronics and aerospace.

High Efficiency Adaptability: Models ranging from manual to fully automatic cover all production capacity scenarios. Fully automatic machines perform 300-800 cuts per hour, accommodating batch production demands exceeding 1,000 pieces daily.

Wide Material Compatibility: Compatible with pure aluminum, aluminum alloys, and other aluminum materials, while also handling copper cutting. By replacing specialized saw blades, it processes aluminum parts of varying thicknesses (1-200mm) and accommodates special operating conditions.

Stable and Energy-Efficient Operation: Heavy-duty chassis + precision guide rail design minimizes vibration. Transmission system lifespan exceeds 100,000 hours with a failure rate below 0.5%. Premium models reduce energy consumption by 30% compared to traditional equipment.

Easy Operation and Maintenance: Modular design facilitates quick replacement of saw blades and components. High-end models feature intelligent functions like automatic oil spraying and AI optimization, minimizing manual intervention and material waste (achieving 98.5% utilization rate).

Comprehensive Safety: Equipped with protective covers, emergency stop buttons, and leakage protection devices. Select models incorporate infrared sensors that automatically halt operation when personnel approach the cutting zone, reducing operational risks.

Aluminum Cutting Machines: Core Equipment for Aluminum Processing and a Scientific Selection Guide

In modern industrial systems, aluminum alloys have become foundational materials across construction, automotive, aerospace, and electronics sectors due to their unique advantages of lightweight, high strength, and corrosion resistance. As the core equipment in aluminum processing, the performance of aluminum cutting machines directly determines processing efficiency, product precision, and production costs. From manually operated compact units to fully automated intelligent systems, the evolution of aluminum cutting machines has consistently aligned with industrial upgrades, serving as a key force in expanding the boundaries of aluminum applications.

I. Core Analysis of Aluminum Cutting Machines: A Comprehensive Understanding from Principle to Application

1. Core Working Principle and Composition

The core operational logic of aluminum cutting machines is based on the innovative concept of “fixed workpiece, moving tool.” An electric motor drives the cutting tool to rotate at high speeds, working in conjunction with a precision feed system to shear and separate aluminum materials. This fundamentally resolves issues prevalent in traditional processing, such as high energy consumption, significant vibration, and poor cut quality. Its key components comprise three major systems: - Power System: Typically employs AC servo motors with high-precision position control, enabling flexible speed adjustment based on aluminum properties. - Cutting System: Features carbide or diamond-coated saw blades, usually with 60-120 teeth—more teeth yield smoother cut surfaces. - Control System: Utilizes CNC modules for parameter presetting and automated cycles; high-end models integrate AI algorithms to optimize cutting paths.

2. Mainstream Types and Application Scenarios

Based on automation levels and processing capabilities, aluminum cutting machines fall into four categories to suit varying production scales:

- Manual aluminum cutting machines: Rely on manual feeding, positioning, and cutting. They offer flexible operation at a lower cost (approximately ¥15,800–38,000), making them suitable for small workshops or infrequent, small-batch cutting tasks. Precision ranges from ±0.2–0.5mm.

- Semi-automatic aluminum cutting machines: Automate the cutting action while requiring manual assistance for loading. They balance efficiency and cost, suitable for medium-volume production in small to medium-sized enterprises, such as daily operations in door and window fabrication shops.

- Fully Automatic CNC Aluminum Cutting Machine: Integrates automatic feeding, sizing, clamping, and unloading. Supports multi-angle cutting (45°, 90°, etc.) with precision up to ±0.05-0.1mm. Achieves 300-800 cuts per hour. Core equipment for aluminum profile mass production, widely used in automotive components, building curtain walls, etc. Price range: ¥50,000-¥200,000+.

- Specialized Aluminum Cutting Machines: Includes high-speed cutters (suited for 1-10mm thin aluminum parts like electronic enclosures) and heavy-duty cutters (capable of processing 100-200mm thick aluminum for aerospace component fabrication), requiring customization for specific operational conditions.

3. Core Application Fields

Aluminum cutting machines permeate all industrial production stages:

- Construction: Precisely cuts door/window profiles and curtain wall studs for seamless integration.

- Automotive: Processes lightweight body frames and wheel hubs to meet weight reduction demands.

- Electronics: Delivers high-precision cuts for heat sinks and equipment housings.

- Aerospace: Meets stringent machining standards for spacecraft aluminum alloy structural components.

II. Scientific Selection: Crafting an Aluminum Cutting Machine Solution Tailored to Your Needs

When selecting an aluminum cutting machine, avoid the misconception that “higher specifications are always better.” Instead, establish a comprehensive evaluation system centered on processing requirements, operating costs, and after-sales service. The following six core dimensions are key considerations for ensuring equipment suitability.

1. Precisely Match Processing Requirements

Processing needs form the logical starting point for selection. Three core parameters must be clearly defined:

- Material Parameters: Identify aluminum type (pure aluminum, aluminum alloy, aluminum tubes/bars/sheets), thickness, and cross-sectional dimensions. For example, cutting 120mm × 80mm aluminum profiles requires equipment matching the maximum cutting specifications. While copper cutting may be compatible, stainless steel cutting necessitates specialized saw blades and reduced rotational speeds.

- Precision Requirements: Electronics and aerospace sectors require CNC models (±0.1mm tolerance). Standard architectural profiles may use semi-automatic models with slightly lower precision. Angular accuracy is equally critical—door/window joints demand ±0.1° angle error control.

- Production Capacity Requirements: Calculate average daily output. For under 500 pieces daily, semi-automatic models suffice; over 1,000 pieces daily requires fully automatic CNC equipment. Avoid “over-sizing” (wasting energy) or “under-sizing” (causing overload).

2. Focus on Core Performance Parameters

Performance parameters directly determine processing quality and efficiency. Prioritize four key indicators:

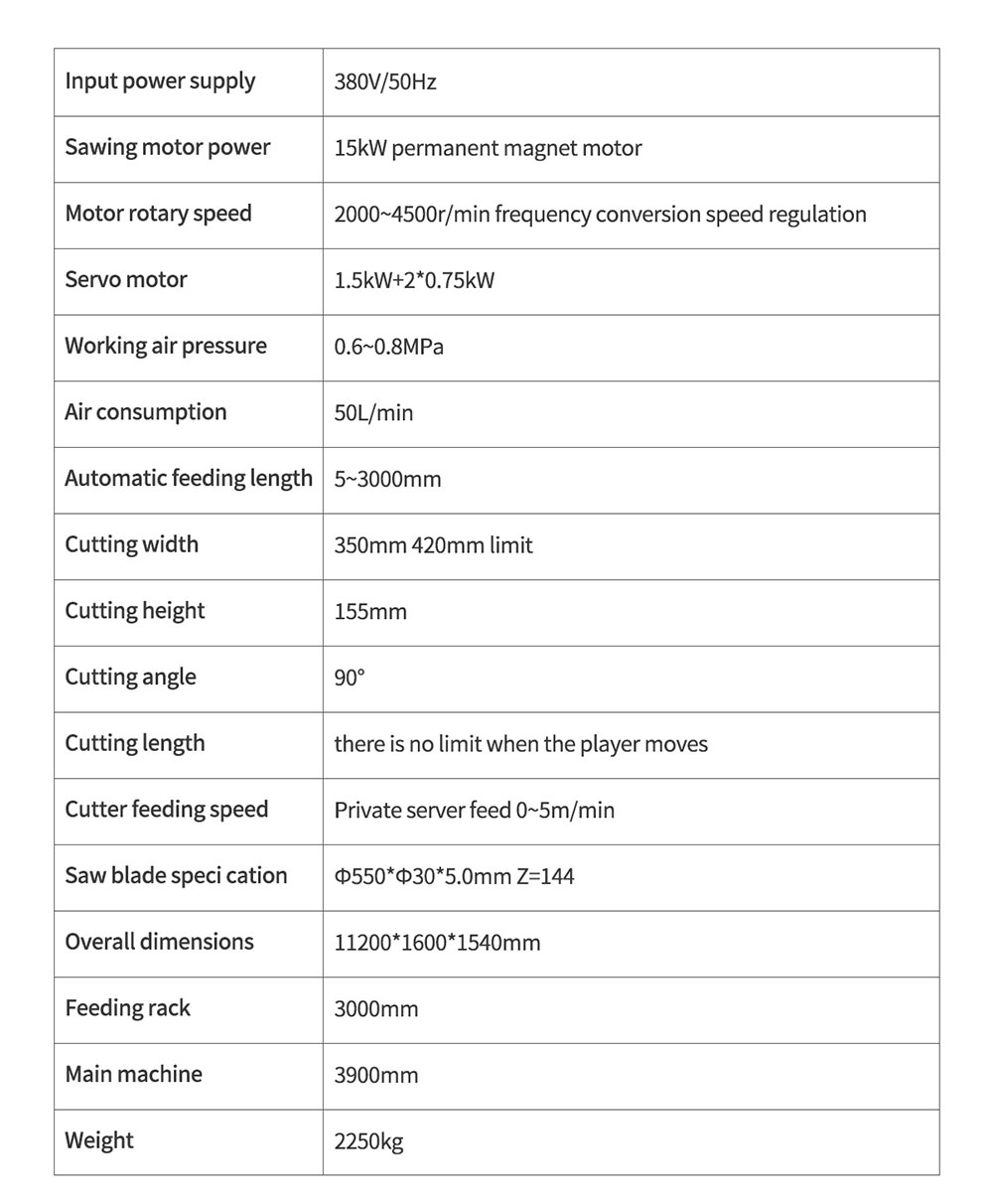

- Drive System: Motor power ranges from 1.5-15kW. Select 1.5-5kW for small equipment and 5-15kW for heavy-duty equipment. Prioritize servo motors, which offer superior response speed and control precision compared to standard asynchronous motors.

The evolution of aluminum cutting machines—from manual operation to intelligent cutting—embodies the journey of industrial automation. Selecting the right aluminum cutting machine is not merely about purchasing equipment; it is a crucial step in building an efficient production system. By precisely matching processing requirements, focusing on core performance, and prioritizing after-sales support, enterprises can avoid resource wastage while ensuring dual improvements in processing quality and efficiency. In today's world where aluminum alloy applications are increasingly widespread, a well-suited aluminum cutting machine will ultimately become a powerful ally in enhancing a company's core competitiveness.

Power System: Motor power 1.5-15kW (small-scale 1.5-5kW, heavy-duty 5-15kW). Servo motors are preferred for superior response speed and control precision.

Cutting Parameters: Saw blade diameter 120-500mm (matched to cutting thickness), rotational speed 3000-4500 rpm (specialized for aluminum alloy), feed rate 20-30m/min for thin materials, 5-10m/min for thick materials.

Stable Structure: Heavy-duty frame + precision guide rails, pneumatic/hydraulic material clamping to prevent deviation, transmission system lifespan exceeding 100,000 hours with failure rate below 0.5%.

Smart Features: Includes automatic oil spraying (reduces aluminum chip adhesion), AI optimization (achieves 98.5% material utilization), multi-specification compatibility (accommodates over 1,000 profile types), and more.

The application of aluminum cutting machines has permeated every aspect of industrial production: in the construction sector, they enable precise cutting of door and window profiles and curtain wall frames, ensuring tight joints; in automotive manufacturing, they meet lightweighting requirements by processing body frames, wheel hubs, and other components; in the electronics industry, they deliver high-precision cuts for heat sinks and equipment housings; and in aerospace, they satisfy the stringent machining standards for aluminum alloy structural components in spacecraft.

Processing requirements serve as the logical starting point for equipment selection, necessitating clarification of three core parameters:

- Material specifications: Identify aluminum type (pure aluminum, aluminum alloy, aluminum tubes/bars/sheets), thickness, and cross-sectional dimensions. For instance, cutting 120mm × 80mm aluminum profiles requires selecting equipment matching the maximum cutting capacity. While copper cutting may be compatible, stainless steel processing demands specialized saw blades and reduced rotational speed.

- Precision requirements: CNC models (±0.1mm tolerance) are essential for electronics and aerospace applications. Semi-automatic machines with slightly lower precision suffice for standard architectural profiles. Angular accuracy is equally critical—door/window joints require ±0.1° tolerance control.

- Production Capacity Requirements: Calculate average daily output. For under 500 pieces daily, semi-automatic models suffice; over 1,000 pieces daily requires fully automatic CNC equipment. Avoid “over-sizing” (wasting energy) or “under-sizing” (causing overload).

2. Focus on Core Performance Parameters

Performance parameters directly determine processing quality and efficiency. Prioritize these four metrics:

- Power System: Motor power ranges from 1.5-15kW. Select 1.5-5kW for small equipment and 5-15kW for heavy-duty equipment. Prioritize servo motors, which offer superior response speed and control precision compared to standard asynchronous motors.

- Cutting Parameters: Saw blade diameters typically range from 120-500mm, matching material thickness; recommended rotational speed is 3000-4500 r/min (for aluminum alloy). Feed rates should be 20-30m/min for thin materials (<10mm) and reduced to 5-10m/min for thick materials (>50mm) to protect the saw blade.

- Stable Structure: Features a heavy-duty frame with precision guide rail design, paired with pneumatic/hydraulic material clamping systems to prevent material displacement during cutting. High-quality equipment boasts transmission systems with lifespans exceeding 100,000 hours and failure rates below 0.5%.

- Smart Features: High-end models incorporate automatic oil spraying systems to reduce aluminum chip adhesion, AI optimization functions that boost material utilization to 98.5%, and multi-specification compatibility systems adaptable to over 1,000 profile types.

3. Evaluating Safety and Maintenance Costs

Long-term operational costs and safety are equally critical:

- Safety Features: Essential components include protective guards, emergency stop buttons, and residual current devices (RCDs). Some high-end models incorporate infrared sensors that automatically halt operation when human proximity is detected in the cutting zone.

- Maintenance Ease: Prioritize modular designs for easy replacement of critical components like saw blades and bearings. Understand blade lifespan (standard alloy blades last 300-500 hours); replace promptly when encountering rough cuts or abnormal noises.

- Energy Efficiency: Products from national-level high-tech enterprises typically reduce energy consumption by 30% compared to traditional models, yielding significant long-term electricity savings.

4. Evaluating Brand and After-Sales Service

As industrial equipment, after-sales service directly impacts production continuity:

- Brand Selection: Prioritize manufacturers certified with ISO 9001, CE, etc., such as Deshang Environmental (precision engineering leader), Jiangyin Haiqing (heavy industry stability specialist), and Wuxi Weien (intelligent manufacturing pioneer). Their clientele includes renowned enterprises like China State Shipbuilding Corporation and Tesla.

- Service Guarantees: Core components should carry 1-2 year warranties. Require 24-hour response times, with over 80% of issues resolved remotely. Engineers must arrive within 48 hours for complex problems. Some manufacturers offer complimentary operator training and video tutorials to reduce personnel learning costs.

5. Verify Actual Machining Performance

Beyond specifications, on-site testing offers the most direct assessment: Bring representative workpieces for test cuts to observe whether cuts are smooth and burr-free, and whether dimensional tolerances fall within acceptable ranges. Run the machine continuously for one hour to evaluate whether it exhibits noticeable vibration or abnormal noise, and whether the interface is intuitive and user-friendly.

6. Balance Budget and Cost-Effectiveness

Related Products

Related News

Submitted successfully

We will contact you as soon as possible