750mm CNC Aluminum Cutting Saw Machine Continuously cutting Suppliers

Ultimate Material Savings & Cost Reduction

High-Precision Stable Machining

Automated Efficient Operation

Safety & Environmental Compliance with Strong Adaptability

Zero Scrap Material Savings, High Precision Stability, Automated Efficiency

Architectural Aluminum Profile Processing Industry (Highest Consumption)

1. Applicable Materials

Core Materials: Various aluminum alloy profiles (6061, 6063, 6005, 7075 series, including solid aluminum bars, hollow aluminum tubes, and special-shaped aluminum profiles);

Compatible Materials: Copper profiles, zinc alloy profiles, PVC profiles (requires specialized saw blades and cutting parameters).

2. Compatible Profile Specifications (based on mainstream models)

Cutting Dimensions: Height ≤155mm, Width ≤420mm (some non-standard models extend to Height 200mm, Width 500mm);

Feed Length: 5mm-6000mm (supports fixed-length cutting, batch segmented cutting, minimum cut length as low as 5mm, zero scrap residue);

Profile Types: Solid aluminum bars, hollow aluminum tubes, open/closed special-shaped profiles, multi-chamber profiles, thin-walled aluminum profiles (air-cushion feeding prevents deformation).

III. Core Application Scenarios

Batch Processing: Single-batch volume ≥500 pieces; zero scrap + high-efficiency cutting rapidly reduces costs;

High-Cost Materials: Significant material savings when processing premium aluminum alloys (e.g., 7075 aerospace aluminum) or large-section profiles (single-piece weight ≥5kg);

High-Precision Requirements: Cutting dimensional tolerances ≤±0.1mm, perpendicularity ≤0.05mm, enabling direct assembly without secondary processing;

Environmental Compliance: Meets workshop requirements for low noise (≤85dB), minimal dust (dust removal efficiency ≥99%), and reduced cutting fluid consumption (near-dry lubrication).

CNC Tail-Free Aluminum Cutting Machine is a specialized cutting equipment designed for aluminum profile processing, emphasizing material savings and high efficiency. It meets the aluminum profile processing needs of multiple industries, including new energy and automotive components. The following details its advantages, features, product introduction, and technical parameters, with specifications presented using several mainstream models as examples:

Advantages and Features

Ultimate Material Savings & Cost Reduction: The core advantage lies in its patented tail-removal structure and split-cutting design, achieving zero tail material residue in aluminum profiles. Compared to traditional aluminum cutters, this increases raw material utilization by over 15%. Certain models incorporate ultra-thin saw blades, reducing kerf loss by over 1.5mm per cut. For large-scale manufacturers, this translates to daily material cost savings exceeding 1000 yuan.

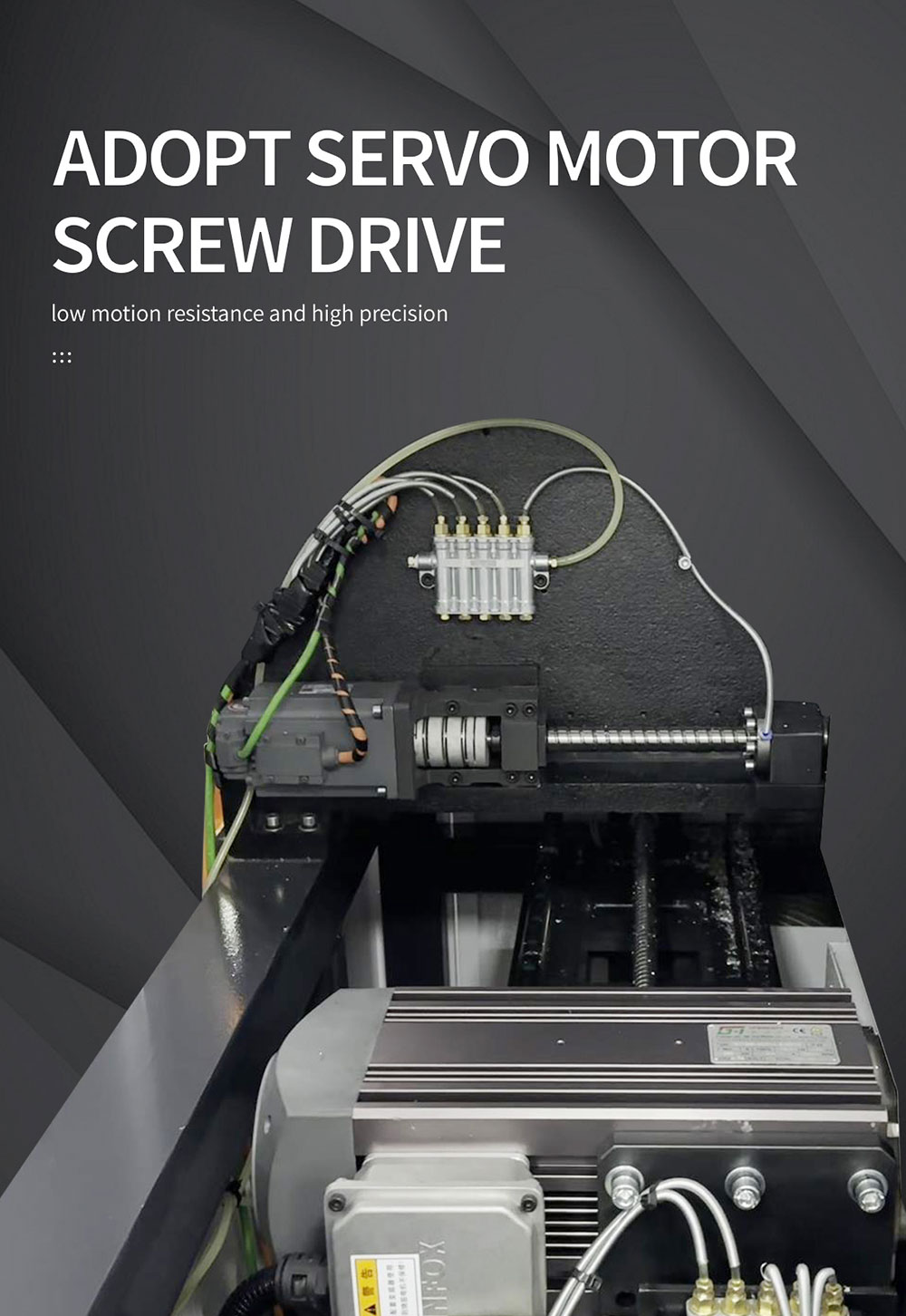

High-Precision Stable Processing: Equipped with a high-precision servo control system and custom spindle, achieving spindle accuracy of 0.01mm. Cutting dimensional tolerances are consistently controlled within ±0.1mm, while cutting perpendicularity and flatness meet stringent standards of 0.05mm and 0.1mm respectively. Combined with a patented separation system and air-cushion feeding mechanism, the cut surface achieves mirror-like smoothness with virtually no burrs, eliminating the need for secondary CNC machining.

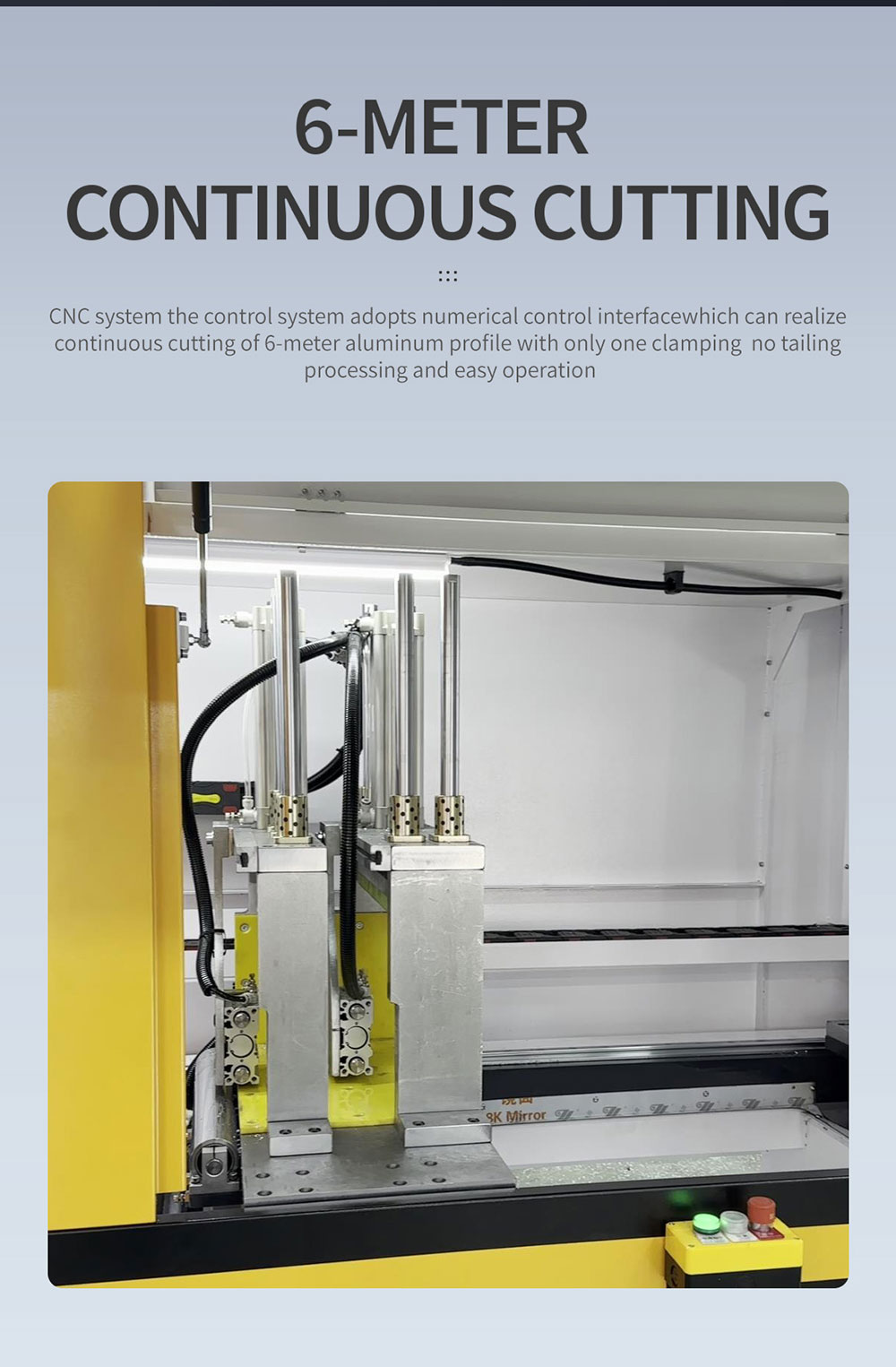

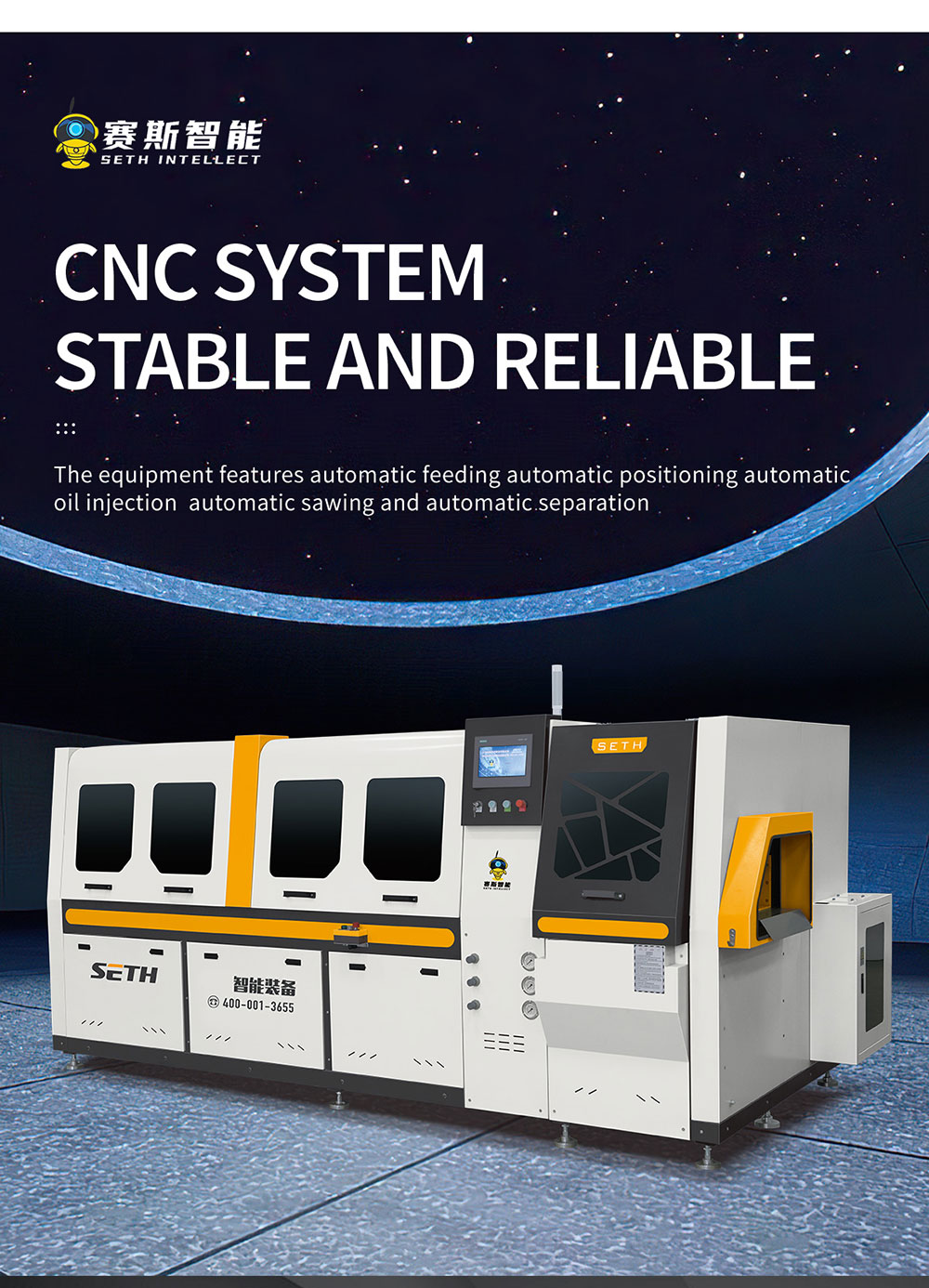

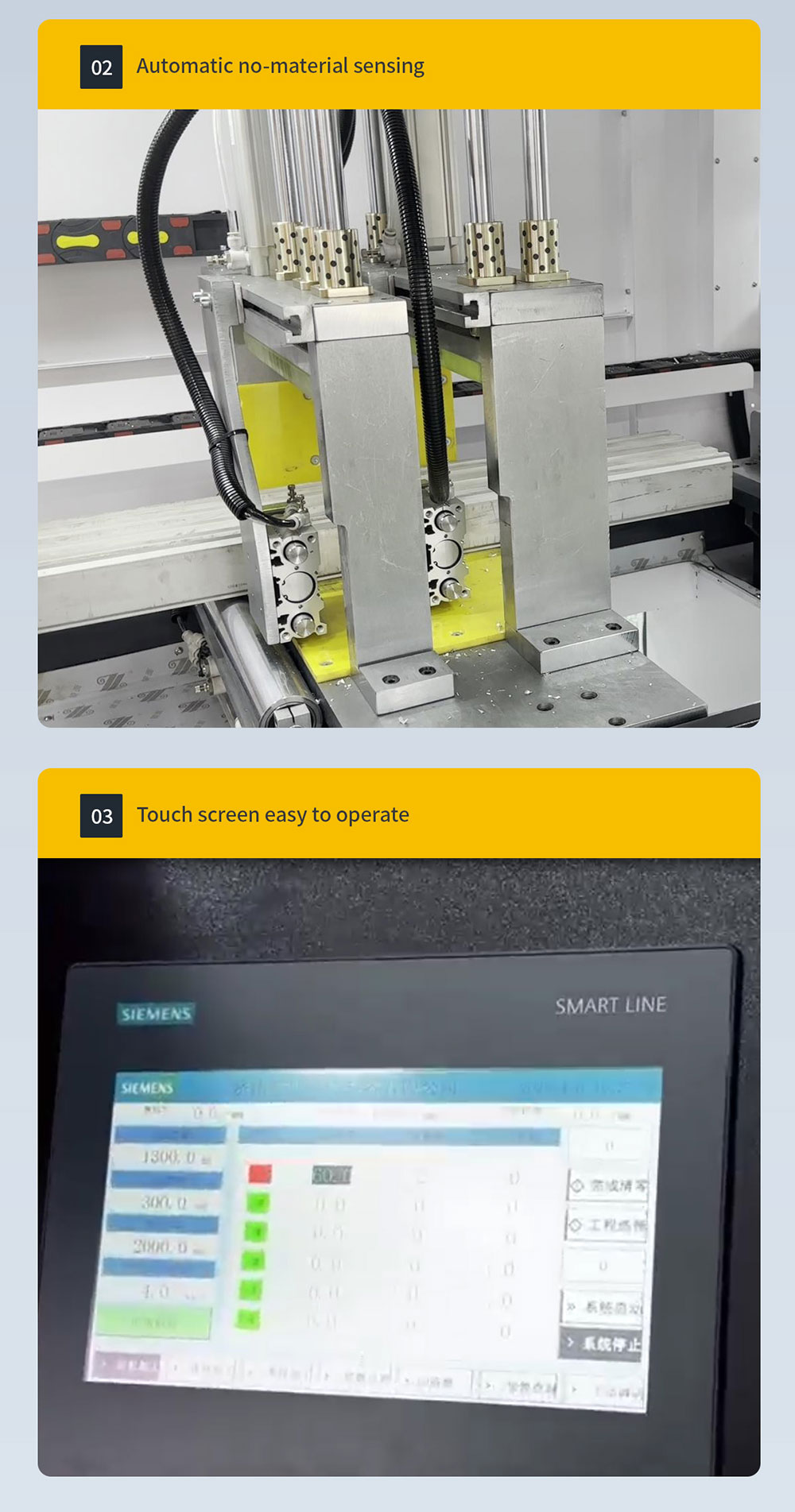

Automated High-Efficiency Operation: Equipped with bus PLC and intelligent CNC systems, it achieves closed-loop control throughout the entire process—automatic feeding, positioning, cutting, and scrap collection. Production efficiency increases by 30% or even up to 4 times compared to traditional equipment. The system supports preset dimension groups for quick recall of different cutting schemes and automatically records processing time and quantity, facilitating cost accounting for enterprises.

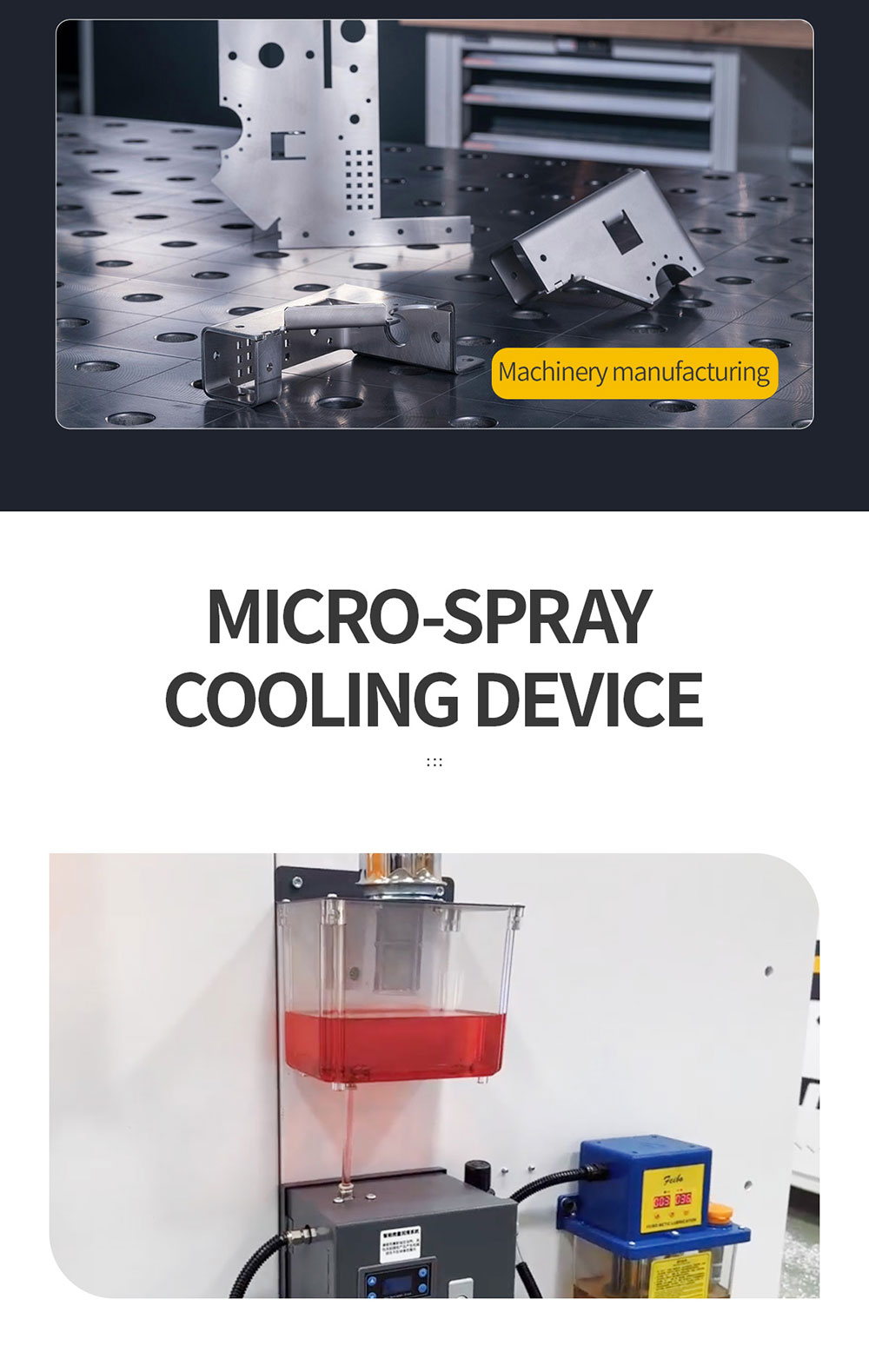

Safety, Environmental Compliance, and Versatility: Most models feature fully enclosed protective covers, with some incorporating sound-absorbing foam to reduce noise by over 15 decibels. Paired with semi-dry micro-lubrication or three-stage dust collection systems, they minimize cutting fluid waste while achieving over 99% dust collection efficiency, meeting green manufacturing standards. Additionally, the equipment allows rapid parameter switching to accommodate diverse materials like aluminum profiles and copper rods, fulfilling processing needs across various industries.

Product Introduction

The CNC Tail-Free Aluminum Cutting Machine is a precision cutting solution developed to address wasteful tailings and low efficiency in aluminum profile processing. Widely adopted across new energy, automotive components, architectural aluminum doors/windows/curtain walls, and solar photovoltaic sectors, its core innovation lies in integrating separable cutting with servo control. The sawing workbench separates via servo motors, paired with an automatic tail-removal mechanism to eliminate waste at its source. This equipment integrates automatic feeding, precise positioning, intelligent cutting, and scrap collection functions. Some models support multi-row and multi-blade cutting, further boosting production capacity. Manufacturers also offer customization services, optimizing parameters such as cutting height, width, and feed length based on customer profile specifications and processing capacity requirements. Non-standard automated cutting lines can even be designed. Some high-end models also feature automatic alerts for material absence and automatic saving of cut counts during power outages, ensuring stable production line operation.

Technical Specifications

Technical parameters vary across manufacturers and models. Below are detailed specifications for two mainstream models, illustrating core configurations for this equipment category:

Parameter Category

Power Supply 380V/50Hz 3

Main Motor Power 7.5kW 15kW (Permanent Magnet Motor)

Servo Motor Power - 1.5kW + 2*0.75kW

Cutting Specifications Height 135mm, Width 350mm

Saw Blade Parameters Diameter 500mm,

Spindle Shank Diameter 30mm Specification Ф550Ф305.0mm, Teeth Count 144

Automatic Feed Length 1500mm 5 - 3000mm

Spindle Accuracy 0.01mm -

Cutting Accuracy Cutting Perpendicularity 0.05mm, Flatness 0.1mm -

Working Air Pressure 0.6 - 0.8MPa

Overall Dimensions 3460×2030×1700mm 6900×1600×1540mm

Equipment Weight : Approx. 2250kg

Special Devices : Micro-mist cooling device

CNC tail-free aluminum cutting machines leverage core advantages of zero-waste material savings, high-precision stability, and automated efficiency. They cater to diverse industries and specifications for aluminum profiles and non-ferrous metal cutting, particularly focusing on scenarios demanding high material utilization, large-batch processing, and stringent precision standards. Specific applications include:

I. Core Target Industries (Prioritized by Demand)

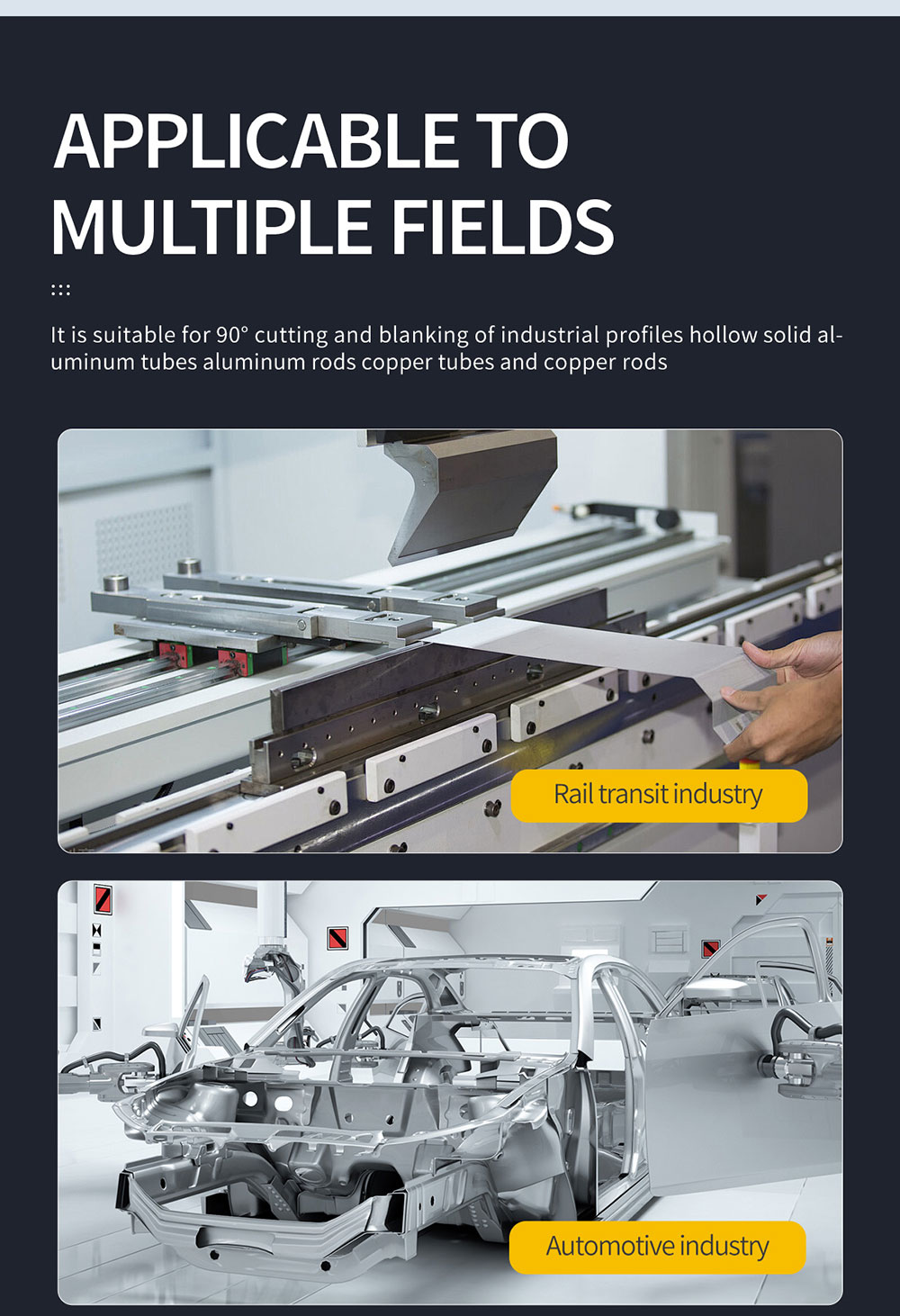

1. Architectural Aluminum Profile Processing Industry (Highest Volume)

Applicable Products: Aluminum door/window/curtain wall profiles (casement window materials, sliding door materials, curtain wall studs), architectural decorative profiles (ceiling studs, partition profiles), aluminum alloy guardrail/handrail profiles, sunroom frame profiles, etc.

Core Requirement Match: Building profiles are typically procured in bulk (single batches exceeding tons). Zero-waste design eliminates the 5%-10% scrap waste common in traditional equipment, significantly reducing raw material costs. Cutting precision (±0.1mm) meets airtightness and aesthetic requirements for profile joints, while burr-free edges minimize post-grinding processes.

2. New Energy Industry (Fastest Growth)

Suitable Products: Aluminum profiles for photovoltaic mounting systems (PV frames, mounting beams/columns), aluminum components for new energy vehicles (battery pack aluminum casings, motor housing profiles, body structure aluminum profiles), aluminum frame profiles for energy storage equipment, etc.

Core Requirements: The new energy sector demands strict material cost control (e.g., annual PV mounting demand exceeds 10 million tons). Zero scrap + ultra-thin saw blades boost material utilization by over 15%. High-precision cutting (verticality 0.05mm) meets assembly requirements for sealing and structural strength, while automated feeding supports mass production (daily capacity exceeding 10,000 units).

3. Industrial Aluminum Profile Processing Industry

Suitable Products: Aluminum profiles for automated equipment (assembly line rails, frame profiles), electronic device enclosures (server cabinets, instrument housings), medical equipment (hospital bed frames, medical carts), and warehousing/logistics applications (shelf beams, pallet box frames).

Core Requirements: Diverse industrial profile specifications (complex cross-sections, varying lengths) require modular equipment design for rapid parameter switching; multi-row/multi-blade sawing accommodates small-batch, high-frequency orders, while precision cutting ensures component interchangeability.

4. Furniture and Home Furnishings Industry

Suitable Products: Aluminum furniture profiles (cabinet door frames, wardrobe side frames, table/chair supports), smart home frames (enclosures for smart door/window modules, TV backdrop aluminum frames), bathroom aluminum profiles (shower enclosure frames, towel rack profiles), etc.

Core Requirements: Home furnishings profiles often require custom specifications (length tolerance ±0.2mm). The CNC system supports multi-group dimension memory for rapid scheme recall. Cutting surfaces are smooth and burr-free, meeting surface requirements for coating and assembly directly, reducing secondary processing costs.

5. Other Sub-Industries

Automotive Components: Aluminum alloy bumper frames, window guide rails, roof rack profiles, etc.

Rail Transit: High-speed rail/subway interior aluminum profiles (handrails, air vent frames).

Electronics & Appliances: Heat sink aluminum profiles, LED lighting housing profiles.

Hardware Fittings: Aluminum hinges, connectors, decorative hardware profiles.

Applicable Materials and Profile Specifications

1. Applicable Materials

Core Materials: Various aluminum alloy profiles (6061, 6063, 6005, 7075 series, including solid aluminum bars, hollow aluminum tubes, and special-shaped aluminum profiles);

Compatible Materials: Copper profiles, zinc alloy profiles, PVC profiles (requires replacement of specialized saw blades and cutting parameters).

2. Compatible Profile Specifications (based on mainstream models)

Cutting Dimensions: Height ≤ 155mm, Width ≤ 420mm (some non-standard models extend to Height 200mm, Width 500mm);

Feed Length: 5mm–6000mm (supports fixed-length cutting, batch segmented cutting; minimum cut length as low as 5mm with zero scrap residue);

Profile Types: Solid aluminum bars, hollow aluminum tubes, open/closed special-shaped profiles, multi-chamber profiles, thin-walled aluminum profiles (air-cushion feeding prevents deformation).

III. Core Application Scenarios

Batch Processing: Single-batch volume ≥500 pieces; zero scrap + high-efficiency cutting rapidly reduces costs;

High-Cost Materials: Significant material savings when processing premium aluminum alloys (e.g., 7075 aerospace aluminum) or large-section profiles (single-piece weight ≥5kg);

High-Precision Requirements: Cutting tolerances ≤±0.1mm, perpendicularity ≤0.05mm, enabling direct assembly without secondary processing;

Environmental Compliance: Meets workshop requirements for low noise (≤85dB), minimal dust (≥99% dust removal efficiency), and reduced coolant consumption (near-dry lubrication).

Summary

The core value of CNC tail-free aluminum cutting machines lies in “material savings + high efficiency + high precision.” They are particularly suited for industries sensitive to material costs and with high-volume batch requirements (e.g., construction, new energy), while also meeting customized, high-precision processing needs (e.g., industrial equipment, home furnishings). These machines represent one of the core devices enabling the transformation of aluminum profile processing from ‘extensive’ to “lean” operations.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible