BAU FBC Window door aluminum curtain wall machinery exhibition

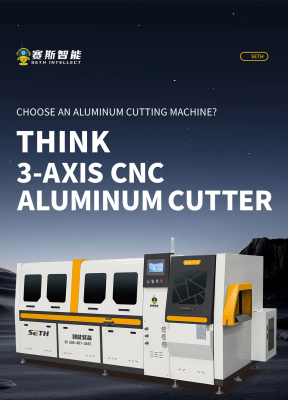

We attened BAU China win-door exhibition and our machines including aluminum window door machinery: cnc double head cutting machine, cnc machining centers, cnc drilling milling machine, cnc corner crimping machine, cnc end milling machines, punching machines ,cnc copy routers etc.

aluminum curtatin wall machinery notching saw, cnc any angle cutting machine, cnc millers etc.

upvc machines: cutting machine, cnc corner cleaning machine, seamless welding machine , glazing bead saw, water slot machine, lock hole machines. Very popular machinery of cutting drilling milling machining centers.

100,000-Square-Meter Mega Exhibition Unveiled:

2025 Shanghai BAU Doors & Windows Show Pioneers Green and Smart TrendsNovember 5, 2025 The highly anticipated BAU CHINA International Building Technology Expo grandly commenced at the Shanghai New International Expo Centre.

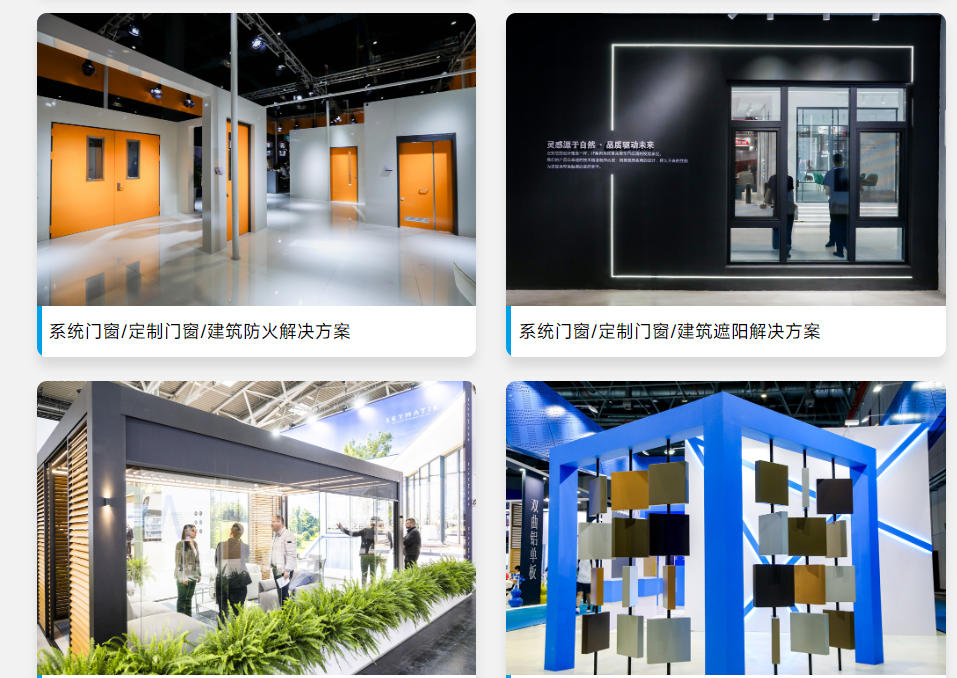

As a core segment of the event, the FBC China International Doors, Windows & Curtain Wall Expo debuted simultaneously. Synergizing with industry flagship exhibitions including the CADE Architecture & Design Expo and R&W China Waterproofing Expo, it collectively formed a flagship joint exhibition spanning 100,000 square meters and gathering nearly a thousand pioneering enterprises worldwide. Centered on the annual theme “Co-Build, Co-Exist, Co-Share,” the expo focused on the green, low-carbon transformation and intelligent technological innovation within the doors, windows, and curtain wall industry.

It attracted over 5,000 international buyers from more than 70 countries and 100,000 professional visitors across the construction supply chain, establishing itself as Asia's largest and most influential industry event in the building envelope systems sector.The FBC showcased comprehensive innovation achievements across the entire industry chain, featuring exhibits spanning smart window systems, low-carbon building materials, curtain wall structural solutions, and hardware fittings. Over 600 global top brands competed on the same stage, including industry leaders like Far East Curtain Wall and Dadi Curtain Wall, alongside cross-industry participants such as Huawei and GLUDA.

The expo featured three core thematic zones: - The International Green & Low-Carbon Zone focused on clean energy applications and carbon-neutral solutions, showcasing eco-friendly products like passive windows and recycled-material curtain walls. - The Future Curtain Wall Zone presented 1:1 scale models demonstrating ultra-lightweight solutions for super high-rises, smart ecological curtain walls, and photovoltaic integration technology, highlighting innovative double-curved surface processes and digital construction solutions. The Building Super Energy Efficiency Special Zone centers on ultra-low energy consumption technologies, integrating smart control systems with renewable energy applications to set new industry benchmarks for energy efficiency. Technological innovation emerged as the exhibition's central highlight. Glodon unveiled its AecGPT large-scale model for the construction industry, introducing AI-driven solutions covering the entire lifecycle of window/curtain wall design, cost estimation, and construction—providing a core engine for the sector's digital transformation. Multiple companies showcased smart door and window systems featuring remote control and environmental adaptive adjustment. Meanwhile, products like energy-saving glass and sealing materials in the low-carbon building materials zone achieved new levels of thermal conductivity reduction through technological upgrades, supporting the construction industry's “dual carbon” goals. Concurrent industry forums featured in-depth discussions among policymakers, architects, and corporate representatives on topics including “Low-Carbon Transformation Pathways for the Door, Window, and Curtain Wall Industry” and " Smart Construction and Industrial AI Applications," offering insights for the industry's high-quality development. Notably, this exhibition strengthened international cooperation and business matching functions.

Organizers specifically recruited overseas buyers from the Middle East, Asia-Pacific, Europe, and the Americas, building bridges for Sino-foreign enterprise collaboration through customized matchmaking services. Renowned door and window enterprises from Germany, Italy, and other countries introduced cutting-edge international design concepts and manufacturing technologies, reaching multiple cooperation agreements with domestic companies in areas such as R&D and cross-border trade. Concurrently held with the 2025 China International Import Expo, the exhibition provided dual trade resources for exhibitors and buyers, further expanding the boundaries of industry collaboration.Exhibition organizers stated that as Asia's core platform for building system solutions, the 2025 Shanghai BAU Doors & Windows Exhibition not only showcased the industry's trends toward greening, intelligentization, and internationalization but also served as a vital vehicle for technical exchange, commercial cooperation, and trend analysis through comprehensive industry chain resource integration and innovation displays. The exhibition will run through November 8. Visitors can pre-register for free admission tickets via the “Shanghai Exhibition Information Network” official account and enter with real-name verification using their ID cards.

Participating in the 2025 Shanghai BAU Exhibition: Charting the Course for Equipment Innovation Amidst Industry Trends

As the closing bell sounded for the 2025 Shanghai BAU Exhibition, reviewing the thick binder of cooperation proposals and market research notes compiled by our team, I was profoundly struck by the impact and inspiration this industry gathering delivered. For me, as the head of a company with over a decade of expertise in door and window equipment manufacturing, these four days were not merely a journey of brand promotion but a journey of understanding the industry's future.

The most striking observation at this exhibition was how green and low-carbon initiatives have evolved from industry aspirations into mandatory benchmarks for equipment development. In the international green and low-carbon theme zone, we witnessed downstream door and window manufacturers' urgent demand for energy-efficient processing equipment—many visitors directly inquired about energy consumption parameters. A curtain wall company executive candidly shared: “Securing green building projects now requires not only compliant window and door products but also production energy consumption data to be included in evaluations.” This unexpectedly propelled our “Variable Frequency Energy-Saving Profile Cutting Center” into the spotlight. Its 30% electricity savings and 15% material utilization improvement precisely address current market demands. Comparing exhibits from competitors revealed that “energy efficiency” permeates every detail of equipment manufacturing—from low-energy motors to intelligent scrap recycling systems—clearly charting our future technical upgrade path.

The depth of intelligent transformation far exceeded expectations, revealing immense potential for cross-industry integration. While the AecGPT large model released by Glodon sparked heated discussions at the industry forum, our technical team was addressing customer inquiries about “digital equipment integration” at our booth. During the exhibition, industrial internet solutions presented by tech giants like Huawei resonated remarkably with our “Remote Maintenance System for Smart Production Lines.” One client immediately expressed a need for seamless integration between processing equipment and door/window design software to minimize data discrepancies at the source. This demand for “equipment + digital” integration is equally strong among small and medium-sized door and window manufacturers. They seek both the efficiency gains from fully automated assembly robots and equipment adaptable to small-batch, multi-variety orders. This aligns perfectly with the flexible production lines showcased by peers like Xinneng, providing concrete evidence for optimizing our product portfolio.

The exhibition's business matching efficiency yielded substantial results. The organizers' customized matchmaking service connected us precisely with three Middle Eastern buyers. Their demand for high-performance thermal break aluminum processing equipment perfectly matched our newly developed “Ultra-Precision Machining Center,” which is now in the sample testing phase. Among domestic clients, window and door manufacturers from the Yangtze River Delta region were particularly focused on machining precision. When we demonstrated the equipment's ±0.1mm accuracy control capability on-site, many companies immediately confirmed their cooperation intentions. Even more unexpectedly, cross-industry collaboration opportunities emerged. A photovoltaic company proactively approached us to discuss developing specialized processing equipment for photovoltaic integrated doors and windows. This collision of cross-sector demands sparked inspiration that closed-door R&D could never yield.

Walking through the dispersing exhibition halls and glancing back at the figures still engaged in discussions, I deeply grasped the true value of the BAU exhibition: it serves not only as a platform connecting equipment with customers but also as a convergence point for industry intelligence. Here, we witnessed market validation for our products while gaining clear awareness of gaps in areas like AI vision recognition and flexible production. The exhibition's conclusion marks not an endpoint but a new beginning. Armed with 58 valid demand questionnaires, 6 cooperation proposals, and profound industry insights, we've already begun adjusting our R&D roadmap. Perhaps at the next exhibition, we'll showcase an intelligent processing system capable of real-time integration with large-scale building industry models.

This exhibition has confirmed that window and door equipment manufacturing is no longer merely mechanical processing. It demands a holistic perspective encompassing building energy efficiency and smart construction. Only by riding the industry wave and transforming customer needs into the driving force of technological innovation can we secure our footing in this race toward high-quality development.