High Speed 4 Axis CNC Machining Centre for Aluminum Profile

Superior Machining Precision

High Processing Efficiency

Strong Profile Adaptability

Stable and Reliable Operation

Convenient Operation and Intelligent Maintenance

Product Introduction :

(1) The 4-Axis Aluminum Profile Portal Machining Center is an automated CNC equipment designed for precision processing of light alloy profiles, positioned as a "multi-process integrated high-efficiency machining solution".

(2)It is widely applicable to aluminum alloy profiles, aluminum-wood composite profiles, UPVC profiles, and copper profiles, meeting precision machining requirements for drilling, milling grooves, chamfering, tapping, and other processes in doors, windows, curtain walls, industrial frames, and rail transit applications. Its core advantages are reflected in three dimensions:

1. Multi-Axis Coordination Precision: Featuring a 4-axis linkage design, the spindle rotates freely within-90° to +90° range, enabling single-stage clamping for multi-surface processing and eliminating positioning errors, achieving machining accuracy of ±0.03mm.

2. High-Efficiency Configuration: Equipped with a 12-station follower tool magazine and automatic tool changer system, combined with dual worktable interaction design, it can process 2 pieces or 2 types of profiles simultaneously, significantly reducing tool change and process conversion time.

3. Stable and Reliable Structure:

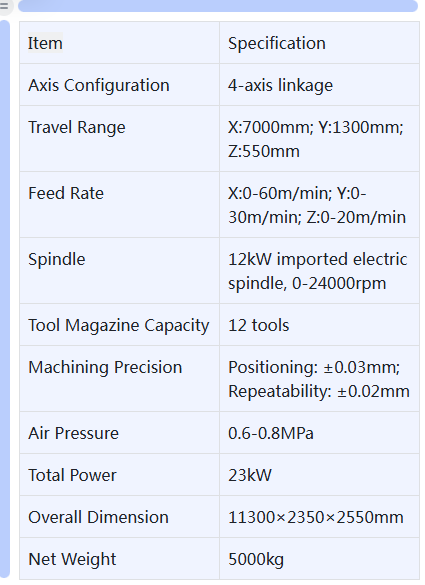

Adopting a portal frame layout with a bed welded from steel plates and time-tempered, paired with imported high-precision linear guides, ball screws, and servo motors, ensuring stability during high-speed operation (X-axis movement speed up to 60m/min). II. Core Technical Parameters Based on mainstream market models GSG ZB-CNC-6500 and LGS-CNC-7000, the key parameters are shown in the table below:

Note: The machine can be customized with an extended X-axis length of up to 9000mm to accommodate ultra-long profile processing. III. Working Principle The equipment operates based on the core logic of "Multi-Axis Motion Coordination in CNC Systems", with the specific process divided into six stages:

1. Program Input and Analysis: Generate machining codes through CAD/CAM software or directly call preset macros, then import them into the CNC system (e.g., B&R Automation System) via a 15-inch touchscreen. The system automatically parses toolpaths, cutting speeds, and other parameters.

2. Workpiece Clamping and Positioning: Place the profile on a pneumatic adjustable fixture. Eight sets of pneumatic clamping plates automatically secure the workpiece. The dual worktable enables synchronized "machining-clamping" operations, reducing downtime.

3. Tool Selection and Replacement: The CNC system controls the tool turret to rotate to the target tool position according to machining program instructions. The robotic arm completes automatic tool change within ≤3 seconds.

4. Multi-Axis Interchangeable Machining: Servo motors drive each axis along preset paths. The X-axis performs longitudinal feed along the crossbeam, while the Y/Z axes move the worktable for lateral and vertical motions. The 4th axis rotates the spindle to specified angles (e.g., 45° chamfering, 90° drilling) for high-speed cutting.

5. Cooling and Lubrication Assurance: During machining, the PLC-controlled spray cooling system cools the cutting area, while the automatic lubrication system applies timed lubrication to moving parts like guides and lead screws to reduce wear.

6. Process Completion and Reset: After completing the process, the equipment automatically returns to the starting position, releases the fixture, and removes the workpiece. The system enables remote data traceability and maintenance reminders through connected devices.

The 4-axis aluminum profile gantry machining center is a high-precision CNC equipment designed for integrated processing of light alloy profiles. It is specialized in milling, drilling, tapping, chamfering, and grooving operations on aluminum alloy, aluminum-wood composite, u-PVC, and copper profiles, widely applied in door/window curtain walls, industrial frames, and rail transit industries. Key advantages include: 4-axis linkage capability: Spindle rotates within -90°~+90° for multi-surface processing in one clamping, ensuring positioning accuracy of ±0.03mm; High-efficiency configuration: 12-station tool magazine with auto tool change, paired with dual worktables for simultaneous processing without interference; Stable gantry structure: Welded steel bed, imported linear guides and servo motors enable X-axis speed up to 60m/min.

3. Working Principle The equipment operates based on CNC system-controlled multi-axis coordination, following these steps: Program Input: Process codes generated by CAD/CAM software are imported via USB or Ethernet into the CNC system; Workpiece Clamping: Profiles are fixed by 8 pneumatic clamps, with dual worktables enabling parallel loading and processing; Tool Changing: The system commands the 12-station magazine to switch tools automatically within 3 seconds; Linked Machining: Servo motors drive X/Y/Z axes for feeding, while the 4th axis adjusts spindle angle. The high-speed spindle performs cutting operations; Cooling & Lubrication: Mist coolant sprays the cutting area, and automatic lubrication maintains guideways and screws; Completion & Reset: The machine returns to home position after processing, with remote monitoring for data tracking.

Superior Machining Precision It adopts 4-axis linkage technology, allowing the spindle to rotate freely within the range of -90° to +90°. This enables multi-surface processing of aluminum profiles in a single clamping, eliminating positioning errors caused by repeated clamping. The machining accuracy can reach ±0.03mm, and the repeat positioning accuracy is as high as ±0.02mm, fully meeting the precision requirements of high-end fields such as door/window curtain walls and rail transit. High Processing Efficiency Equipped with a 12-station follow-up tool magazine and an automatic tool change system, the tool change time is less than 3 seconds, significantly reducing the time wasted in tool replacement. Moreover, the dual-worktable interactive operation design supports simultaneous processing of two workpieces or two types of profiles. While one workpiece is being processed, the other can be clamped, realizing "non-stop production" and greatly improving the overall processing efficiency. Strong Profile Adaptability It is compatible with various materials such as aluminum alloy profiles, aluminum-wood composite profiles, UPVC profiles and copper profiles. For aluminum profiles of different lengths, it can be customized with an extended X-axis (up to 9000mm) to adapt to the processing needs of ultra-long profiles. In addition, it can complete multiple processes such as drilling, milling, chamfering and tapping in one operation, avoiding the need for multiple devices to cooperate, thus saving production space and cost. Stable and Reliable Operation The gantry-type frame structure is adopted, and the bed is made of welded steel plates and undergoes aging treatment, which effectively reduces deformation and ensures the stability of the equipment. It is matched with imported high-precision linear guides, ball screws and servo motors. The X-axis moving speed can reach up to 60m/min, and it can still maintain stable operation at high speed, reducing the failure rate and extending the service life of the equipment. Convenient Operation and Intelligent Maintenance It is equipped with a 15-inch touch screen and a advanced CNC system (such as B&R automation system). Users can import processing codes generated by CAD/CAM software or call preset macro programs, simplifying the operation process. Meanwhile, the system supports remote connection, which can realize real-time tracking of processing data and automatic reminders for equipment maintenance, reducing the difficulty of equipment management and maintenance.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible